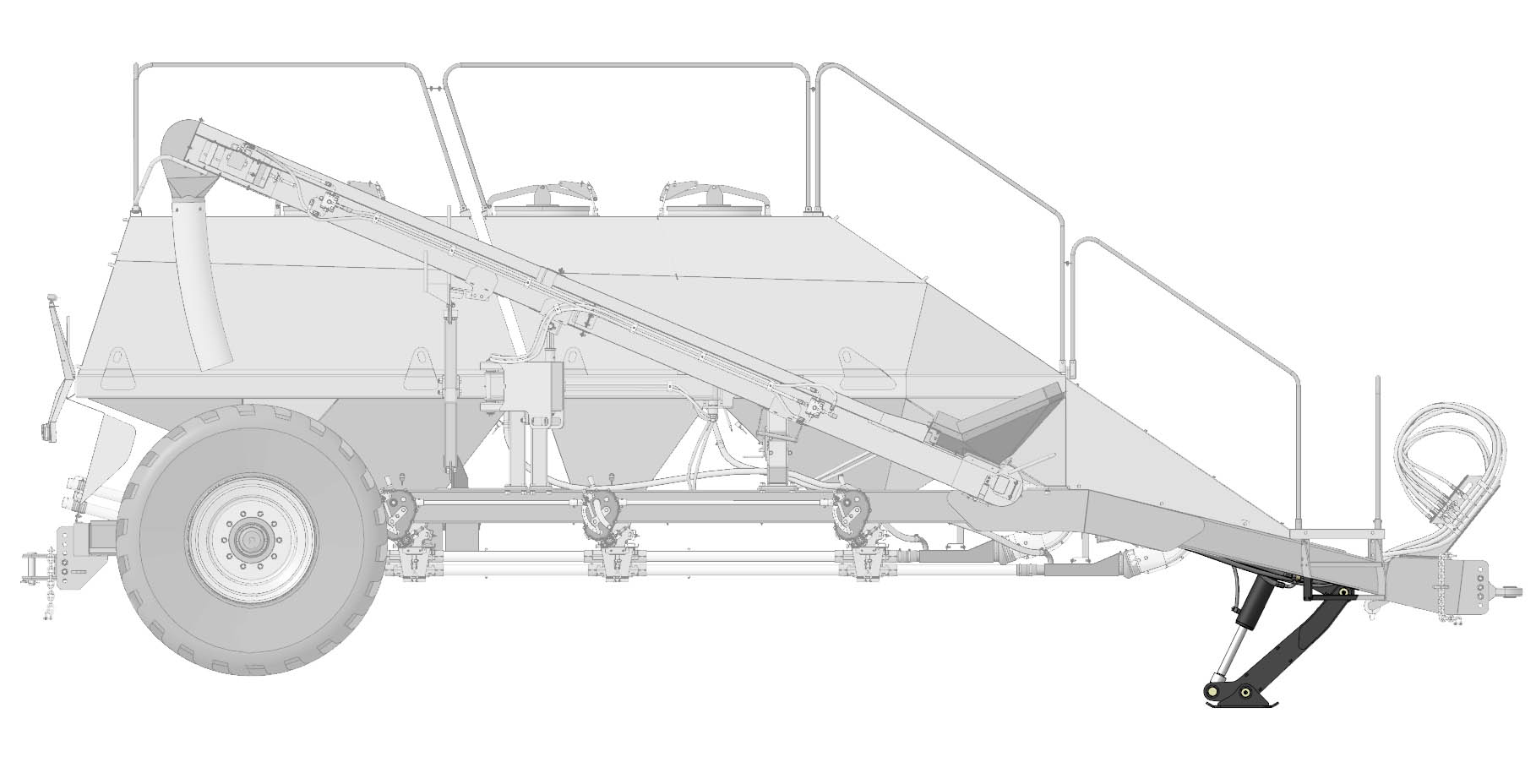

Pneumatic bunker PB-15-1

Three-section pneumatic hopper for seeds and fertilizers FEATAGRO is a high-tech unit that allows you to combine various types of dry granular fertilizers with seeds of grain, leguminous and small-seeded crops when sowing agricultural crops (for example, simultaneously apply starter fertilizers, complex fertilizers and seeds), and an extended range of settings for the seeding units of the hopper allows you to sow forage mixtures (for example, simultaneously sow up to three types of grass or other agricultural crops)

One option for the location of the hopper - front, with a volume of 15 m3 (optional for all series of FEATAGRO seeding complexes, except for the SD series)

The hopper is divided into three parts in a percentage ratio of 35/20/45, which allows you to separate the loading of seeds and dry granular fertilizers

- For operational safety, ladders and fences are installed on the seed hopper, as well as a special anti-slip coating on the surface of the hopper

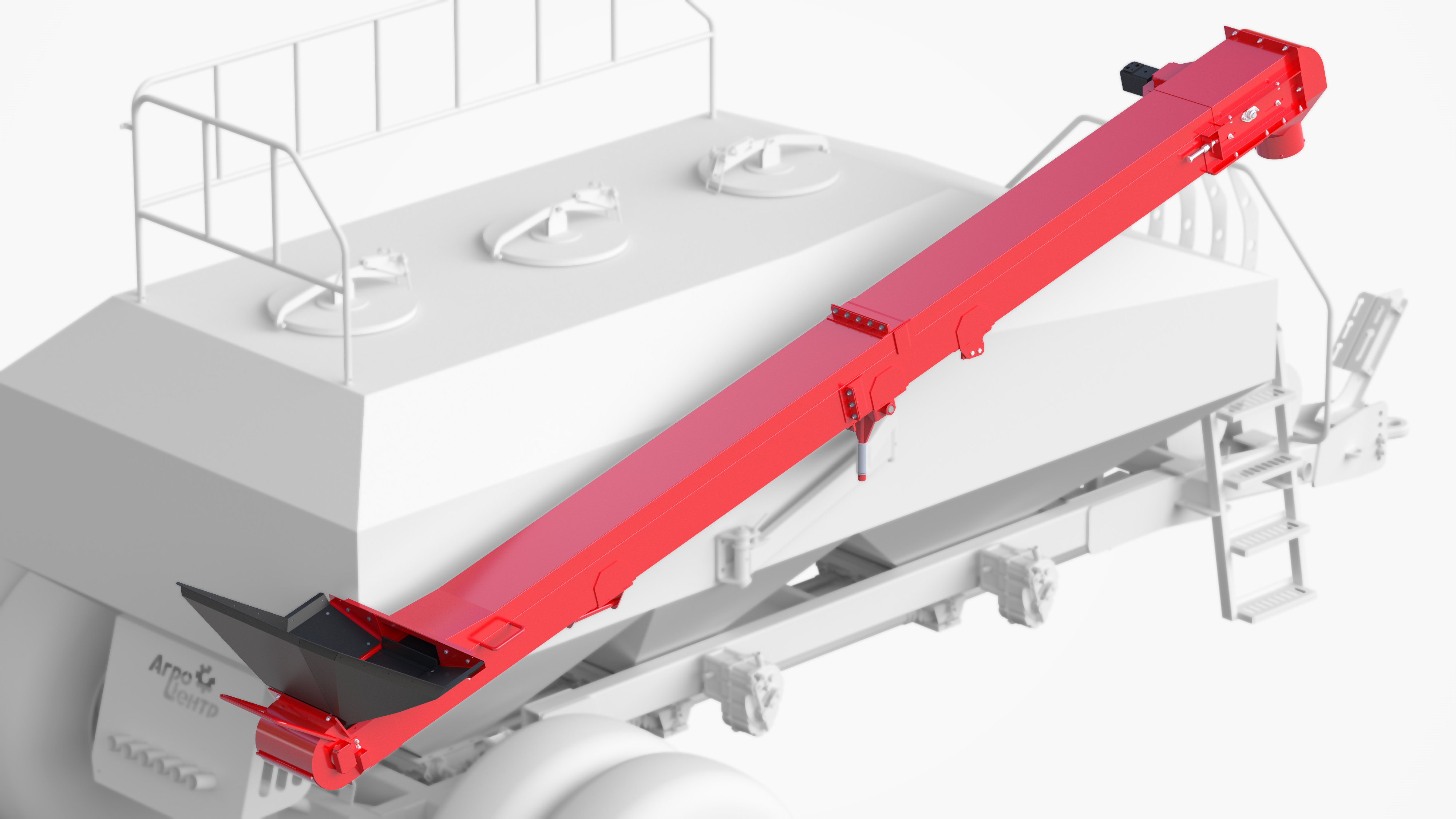

- For quick loading of seed material, a belt conveyor-loader of the seeding complex with LED lighting is installed, which allows to minimize the injury to seeds of grain and leguminous crops, while maintaining a high speed of loading of seed material and fertilizers

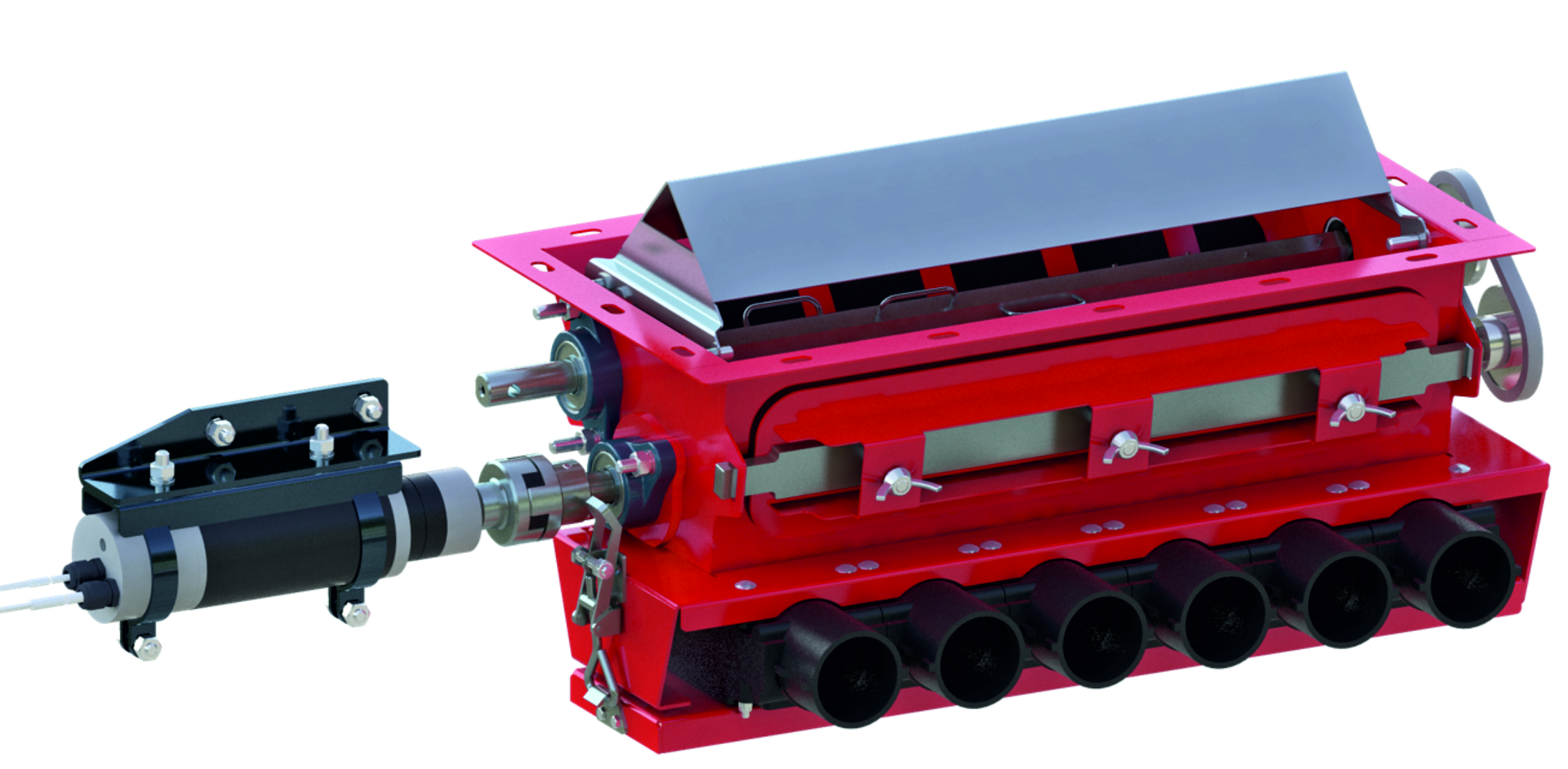

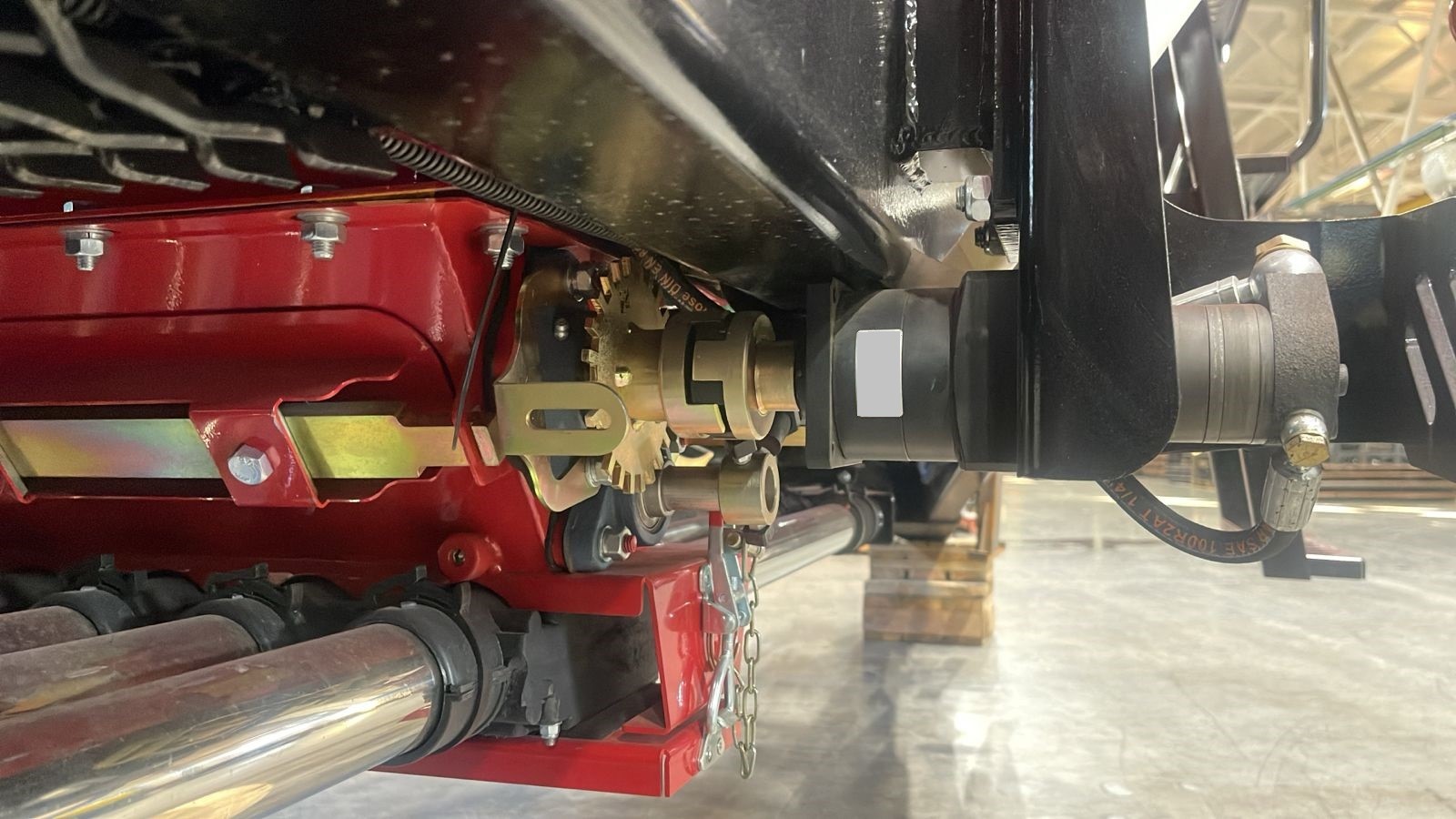

- Twelve-channel distribution of the seed flow (dual-circuit) allows to apply fertilizers and seed material to different depths and to use a three-section pneumatic hopper with various series of FEATAGRO seeding complexes

- Modern composite materials and stainless steel are used in the design of the dispenser, which makes it reliable and durable, even when working with mineral fertilizers

- The kinematic diagram of the drive of the dispensers through the variator has a wide range of change in the speed of rotation of the metering rollers, which allows to set seeding rates from 2.5 to 400 kg / ha

- The set includes 2 types of seeding rollers - standard for sowing grain and leguminous crops; and small-seeded - for sowing small-seeded crops such as rapeseed, camelina, alfalfa and others

- The variator shaft is equipped with a breakaway clutch to prevent breakage in case of clogging of the dispenser coils

- Hydraulic support on the drawbar of the three-section pneumatic bunker allows you to quickly and comfortably connect the entire seeding unit together with any tractor, regardless of the type of its towing device

- The presence of clearance lights allows you to comfortably operate the bunker in the dark

- The bunker is equipped with a SKIF-28 seeding control system from the RADIAN plant, which allows, using sensors, to conduct operational control of all units and systems of the unit

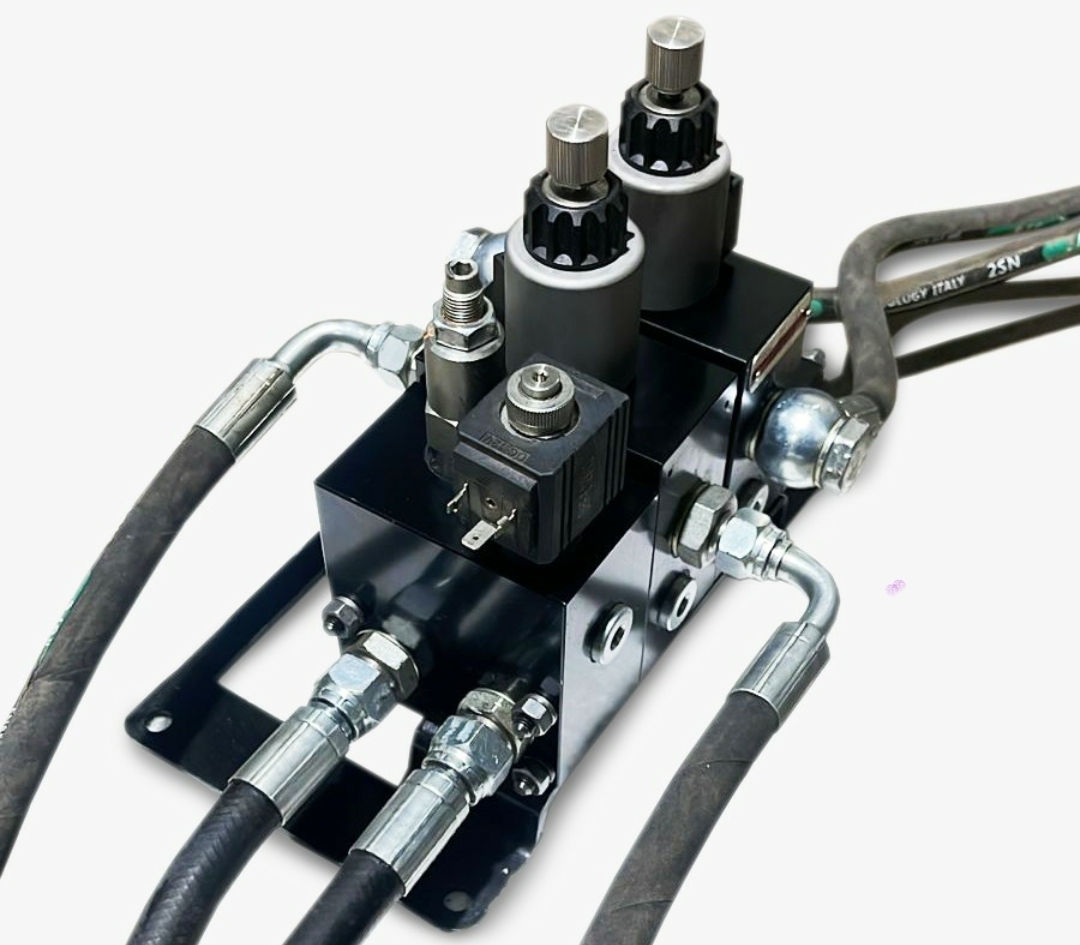

- The hydraulic drive system of the dispensers with software control is designed for the operation of the seeding complex according to task maps, with the possibility of differentiated application of seed material and granular fertilizers, as well as control of the seeding rate through the monitor of the navigation complex.

- The hydraulic drive system of the dispensers with software control ensures the rotation of the seeding rollers of the metering mechanisms in the entire range of speeds and seeding rates of the seeding complex, is an optional replacement for the mechanical drive of the dispensers with a variator, while significantly simplifying the calibration of the dispensers and the setting (change) of the seeding rate of the seed material and granular fertilizers from 2.5 to 400 kg.

- The system is equipped with an individual two-section hydraulic distributor with proportional control of each hydraulic motor, changing the rotation frequency of the seeding roller depending on the speed of the seeding complex and the rate of application of the material.

- Additional requirements for the hydraulic system: Availability of a free flow section of the tractor hydraulic distributor with the ability to adjust the flow of hydraulic fluid. Hydraulic flow – from 60 l/min at 185 bar

- Speed is measured by two independent systems: by GPS signal and by speed sensor. If GPS signal is lost or unstable, the system switches to the signal from the wheel speed sensor.

|

В целях безопасности эксплуатации на семенном бункере установлены лестницы и ограждения, а также специальное противоскользящее покрытие на поверхности бункера |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

.jpg) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Parameter name |

Pneumatic bunker PB-15-1 |

|---|---|

|

Unit type |

Semitrailer. |

|

Operating speed, km/ |

Location of the unit in the hitch |

|

Operating speed, km/h |

Up to 12 |

|

Maximum transport speed, km/h, |

Up to 10 |

|

Total volume of the bunker, m3 |

15 |

|

Filling volume of seeds 50%/fertilizers 30%/fertilizers 20%, m3, not less |

7/5/3 |

|

Seed sowing rate, kg/g Cereals Pulses Small-seeded |

10-350* 35-400* 2,5-40* *based on the width of the seeder up to 10.8 m. |

|

Number of fans, pcs. |

2 |

|

Number of seed tubes, pcs. |

12 |

|

Possibility of combined or separate application of material |

Yes |

|

Overall dimensions, mm: -length -width -heightAnchor |

9100±300 4050± 100 3700 ± 300 |

|

Weight, kg |

6500± 500 |

|

Availability factor taking into account organizational time, not less |

0,98 |

|

service life, years |

7 |

|

warranty service life, years |

1 |

|

Number of personnel by profession required to service the bunker, people |

1 machine operator |

.jpg)