Rollers KIV of METEOR series

The roller model range of FeatAgro brand name is represented by KIV-6 and KIV-9 METEOR rollers perfectly cope with such tasks as filling up, deforming and grinding the postharvest stubble remains of rough agricultural crops: sunflower, corn and others, as well as rolling down of stubble remains or sowing the seeds of various agricultural crops. When using the water-filled grinding rollers, a mixture is created, which decays during autumn and winter and serves as a fertilizer, while exercising a positive effect on the yield. When using the covering rollers, after sowing the seeds of agricultural crops, there is the improved capillary nutrition of the buried seeds and leveling of the covering layer – all of this positively affects the seedling vigor and ensures a higher crop yield.

The roller may be used in all soil and climate zones, except for the hill agriculture zone.

Sound “PRO” arguments for the METEOR rollers:

- high performance at low operating costs;

- they are mated to the tractors of 1.4 – 2 class;

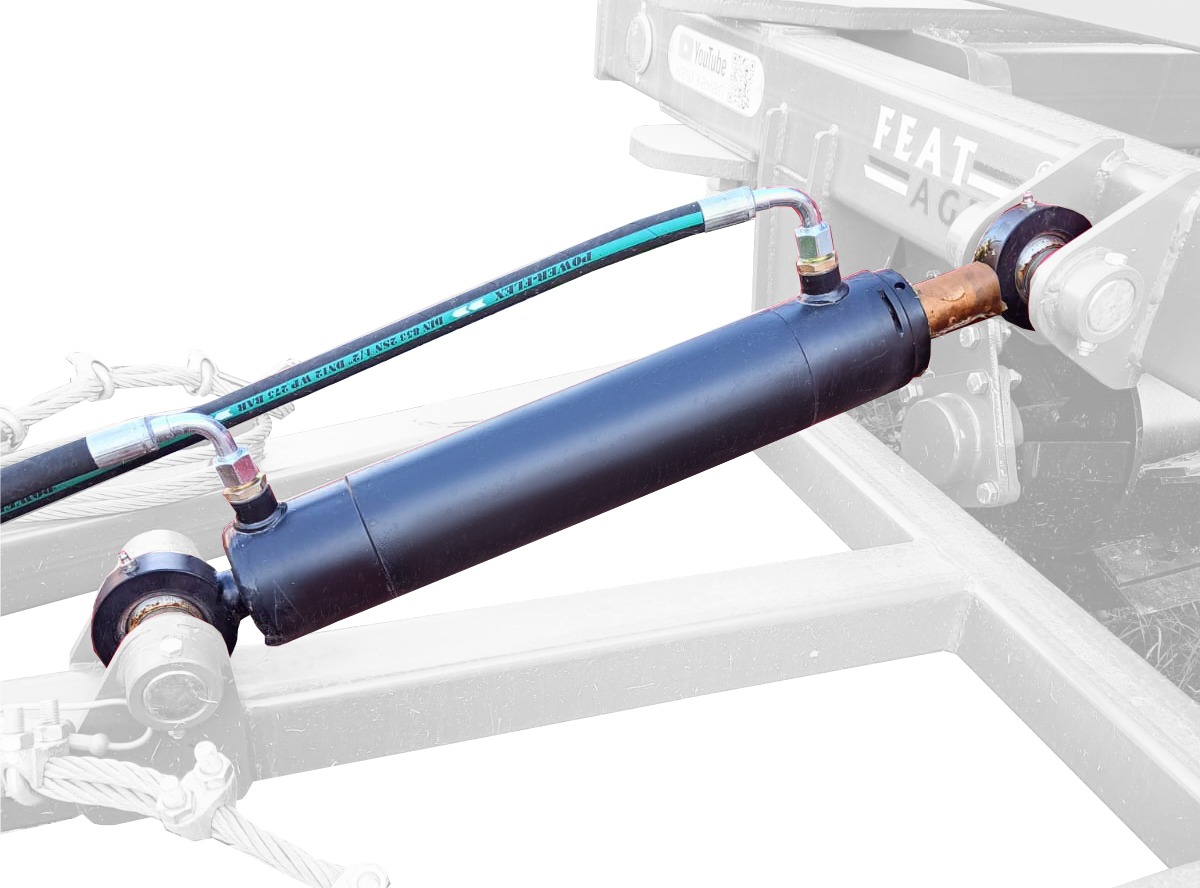

- the units are hydroficated, so they are quickly transferred into the operating or transport position;

- the presence of transport wheels allows to move from field to field rapidly and over considerable distances;

- the frame is made of 09G2S structural steel, which increases the service life and reliability of the machines;

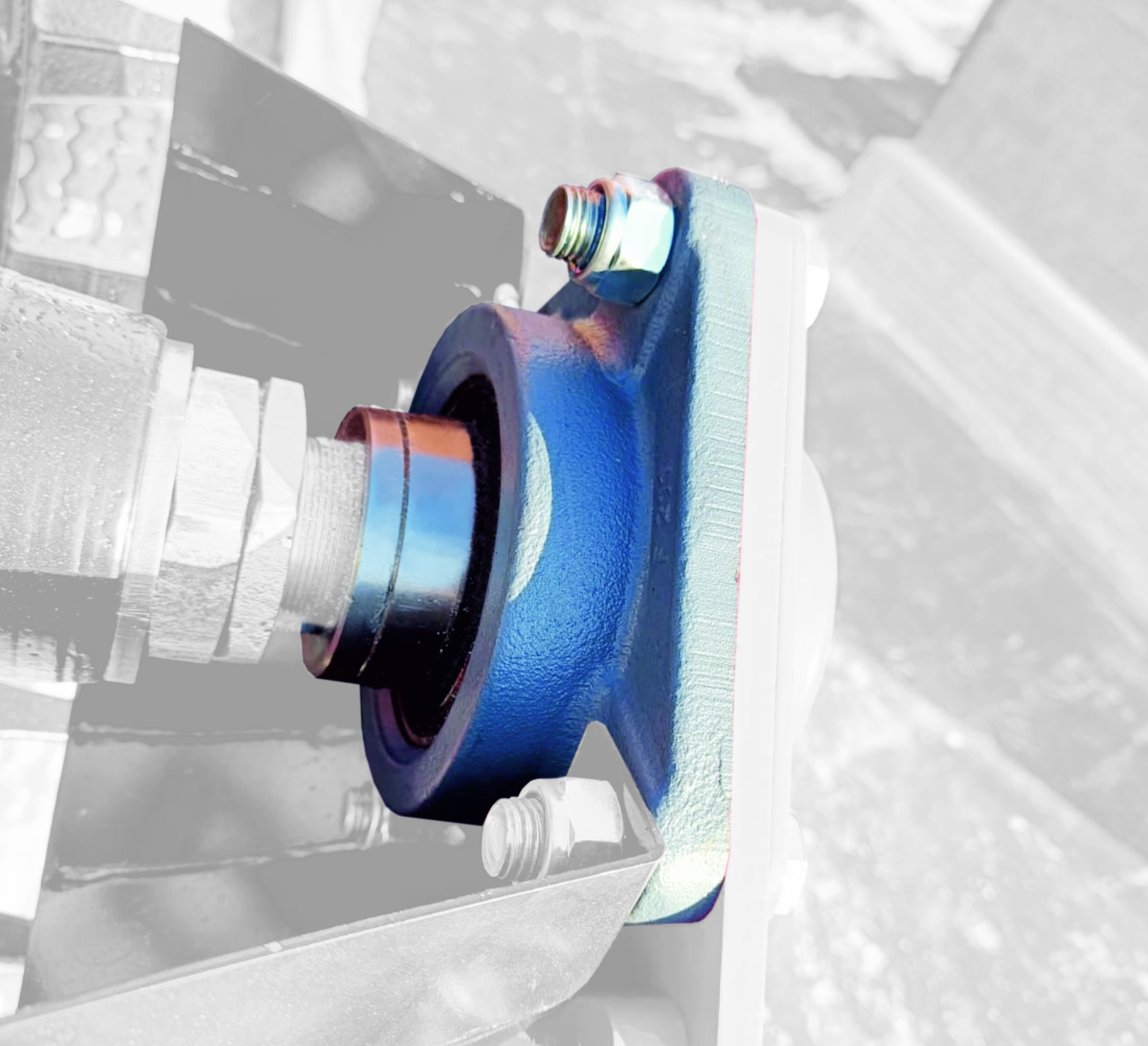

- The KIV-6 and KIV-9 METEOR rollers have reliable bearing assemblies manufactured by FKL (Slovenia) with a special triple seal requiring no maintenance. They have a direct agricultural purpose and meet all the operating requirements under extreme conditions.

Furthermore:

The water-filled grinding rollers:

- promote acceleration of the natural process of soil fertilization – the microorganisms start processing of the ground stubble remains faster;

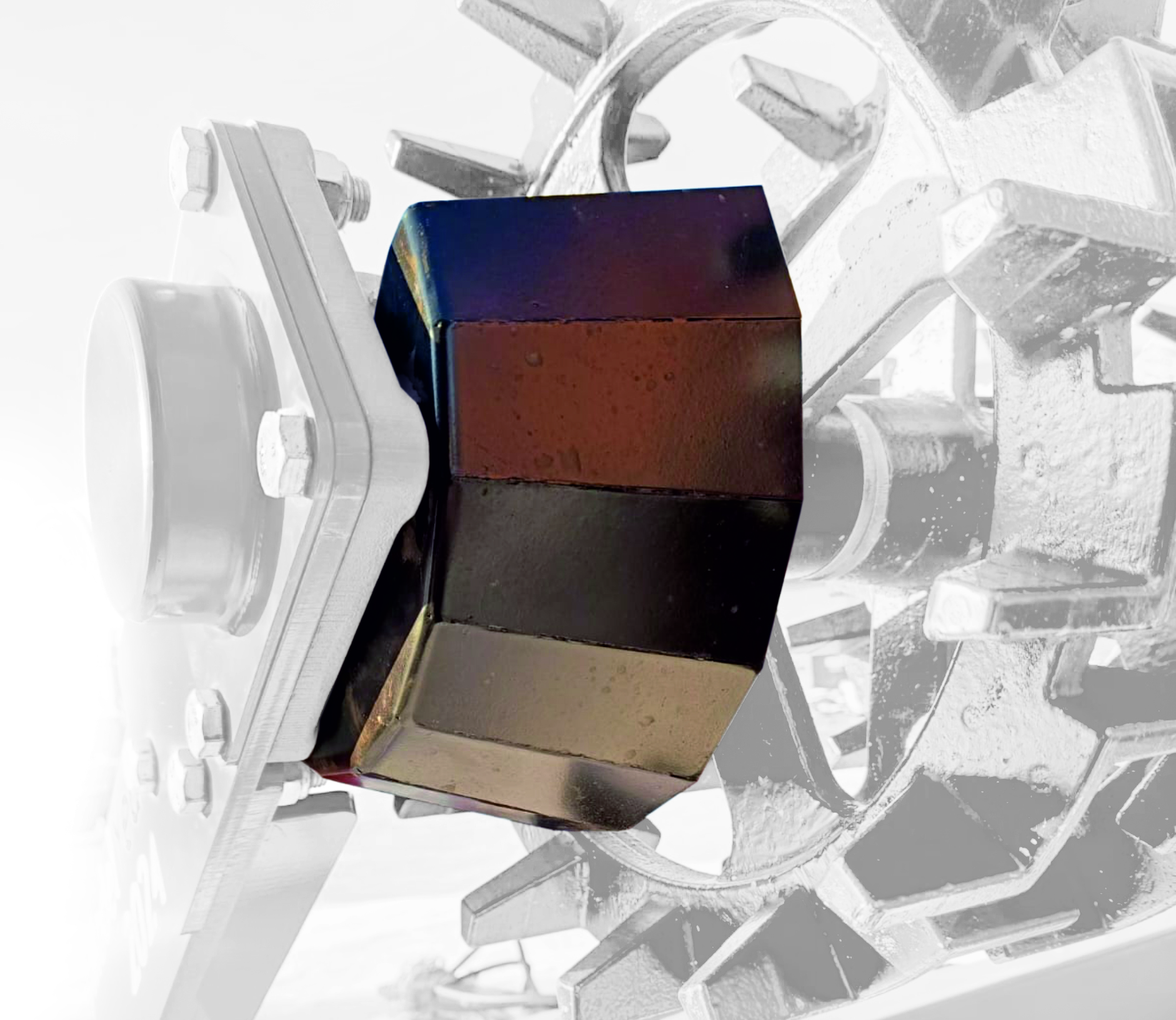

- the cutting knives are located at an angle of 60 degrees, which enables the most efficient processing of the stubble remains of rough crops;

- the cutting knives are made of 65G high-strength steel with volumetric hardening, which improves the performance characteristics of the roller thanks to the uniform product hardness;

- the cutting knives have a crescent-shaped structure formed on the laser equipment, which allows the unit to cut itself more efficiently than the units with the direct arrangement of the knives;

- the rollers are made of 09G2S structural steel, which increases the service life and reliability of the machine;

- due to its own weight and the possibility to increase it with the help of water (there are vessels with caps inside the rollers for filling them with water), the pressure on the soil and stubble remains increases, as a result of which the remains are ground to an extra fine substance. It ensures the metabolism acceleration in the soil and its fertilization.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Parameter Name |

KIV-6 |

KIV-9 |

|---|---|---|

|

Weight, kg |

2400 |

2800 |

|

Weight with the water-filled rollers, kg |

2800 |

3400 |

|

Productivity, ha/hour |

to 7,2 |

to 10,8 |

|

Operating speed, km/h, not more than |

12 |

|

|

Transport speed, km/h, not more than |

15 |

|

|

Operating width, m |

6 |

9 |

|

Number of sections, pcs. |

3 |

5 |

|

Number of knives, pcs. |

96 |

144 |

|

Distance between the cutting edges of the knives, mm |

200 |

|

|

Number of operating staff, persons |

1 |

|

|

Dimensions, mm: |

|

|

|

- length |

3520 |

3520 |

|

- width |

6370 |

9370 |

|

- height |

1000 |

1000 |

|

Dimensions in the transport position, mm: |

|

|

|

length |

4900 |

6400 |

|

width |

2350 |

2350 |

|

height |

1720 |

1720 |

|

Recommended drawbar category of tractors, pulling forces |

1,4 - 2 |

|