Vesna Harrows

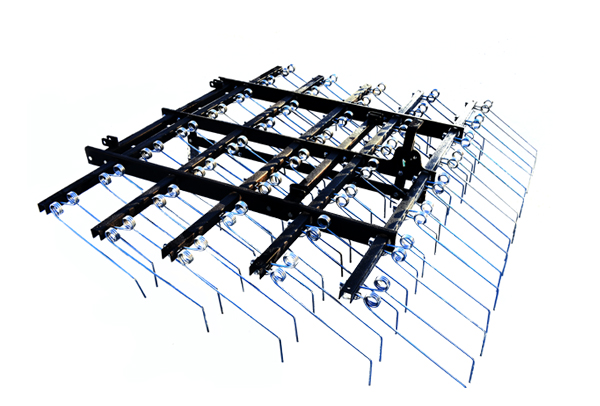

Vesna trailed harrows are intended for stubble breaking and pre-sowing tillage, soil loosening and field surface leveling, mulching, weed sprout keeling, soil lump breaking as well as harrowing shoots of grain and industrial crops.

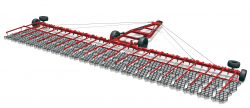

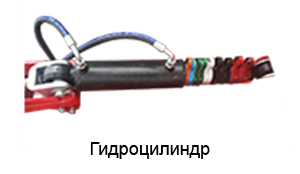

The typical model range is represented by a very practical, mobile and reasonably priced trailed hydroficated coupling of harrow sections in its segment with three variants of working implements with the operating width of 14 m for the tractors of MTZ-82 and МТЗ-1221 class. Using the hydraulic system, without human involvement, the harrow folds out into the operating position, as well as folds up into the transport one.

In case of clogging of the harrow row with stubble remains, the machine operator can automatically clean them, using the hydraulics, by raising the hitch and leaving the stubble remains.

At the customer’s request, the harrow may be completed with one of three types of harrow sections:

- with a forged hardened tooth

- with a straight spring tooth

- with a L-shaped spring tooth (weeder)

|

|

|

| with forged hardened tooth | with straight spring tooth |

with L-shaped spring tooth (harrow)

|

Sound “PRO” arguments for Vesna-14 harrow:

• The operating width of the harrow is 14 m. Its maneuverability and small weight combined with a high operating speed of the tractor with the power from 80 to 130 h.p. provide high performance of the unit;

• The harrow is designed for harrowing both industrial and grain crops;

• There is an option of turning the harrow section frame by 180 degrees for more active impact on the soil (in a zigzag harrow only);

• The harrow helps to perform early spring harrowing, pre-emergent and post-emergent harrowing;

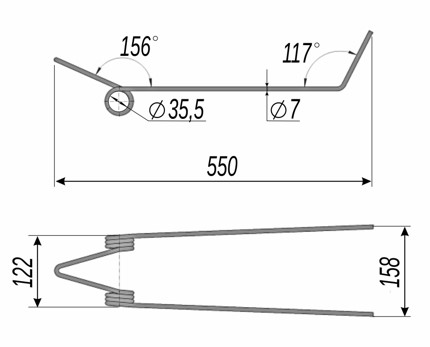

• Practical adjustment of the approach angle of spring teeth on the harrow sections;

• High maneuverability – the frame structure of

the harrow allows to move not only forward but also backward;

• At the customer’s request, the harrow may be completed with one of three types of harrow sections:

- with a forged hardened tooth;

- with a straight spring tooth;

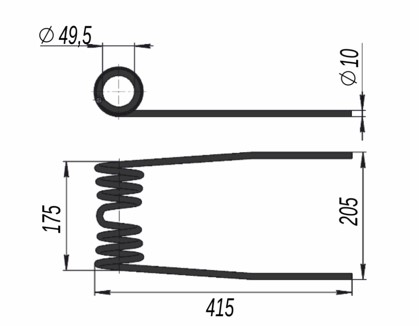

- with a L-shaped spring tooth (weeder);

• When completing the harrow with a forged tooth, the harrow sections are made of rolled strip 40x8, but not chopped one, which allows us to get 100% horizontal of the section without creasing up or down angles and to eliminate shoveling;

• The quality of the metal used excludes its separation during forging;

• The spring teeth of the harrow are made of high carbon alloy steel that is heat-treated to the hardness of 42 ... 48 HRC;

• Using the hydraulics from the tractor cab, the harrow folds out into the operating condition and folds up into the transport one;

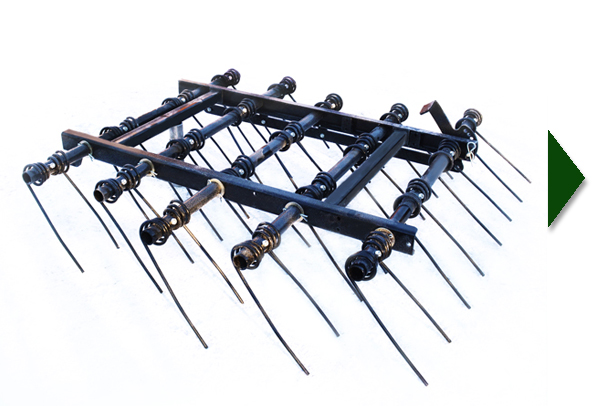

• The chained fastening of the harrow section ensures operation in the “floating” position;

• A row of the harrow sections mounted one after another on one frame allows to fulfill the functions assigned to them more effectively and fully;

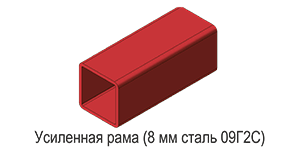

• The frame structures are produced from thick-walled non-circular pipes from 09G2S alloy steel;

• The mechanical cleaning of the harrow sections is carried out using the tractor hydraulics;

Attention! There is an opportunity to implement coupling without the harrow sections with the respective price reduction.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

По желанию заказчика комплектуется одним из трёх видов звеньев бороны: |

||

|

- при комплектации бороны кованым зубом, звенья борон изготавливаются из катаной полосы 40х8, а не рубленой, что - позволяет получить 100% горизонталь звена без заломов углов вверх или вниз, исключается нагребание; - качество применяемого металла исключает его расслоение при ковке; - предусмотрен вариант поворота рамки звена бороны на 180 градусов для более активного воздействия на почву (только у зубовой бороны зиг - заг); |

|

|

- практичная регулировка угла атаки пружинных зубьев на звеньях бороны; - пружинные зубья бороны изготавливаются из высокоуглеродистой легированной стали, термообработанной до твердости 42...48 HRC; |

|

|

|

- практичная регулировка угла атаки пружинных зубьев на звеньях бороны; - пружинные зубья бороны изготавливаются из высокоуглеродистой легированной стали, термообработанной до твердости 42...48 HRC; |

Внимание! Предусмотрена реализация сцепки без борон "Зиг-Заг" с соответствующим уменьшением цены.

|

Parameter Name

|

Vesna-14 |

|

|

Operating width, m |

14 |

|

|

Productivity per 1 hour of basic time (at the speed of 12 km/h), ha, not less than |

11,2 |

|

|

Number of harrow sections, pcs. |

14 |

|

|

Number of section rows, pcs. |

1 |

|

|

Operating depth, mm |

20-80 |

|

|

Operating speed, km/h |

12-18 |

|

|

Transport speed, km/h, not more than |

20 |

|

|

Dimensions in the operating position, mm: |

length |

9200 |

|

width |

14500 |

|

|

height |

700 |

|

|

Weight, kg |

1750 +/- 150 |

|

|

Service life, years |

7 |

|

|

Number of operating staff, persons |

1 |

|