Sowing complexes of the AP serieswith seeding in an anchor coulter on a rack with a parallelogram attachment with two support-collecting wheels and an adjustable individual rolling wheel allows you to pass through crop residues without hindrance, easily adjust the coulters and sow crops at high speeds up to 20 km/h.

High-precision application of seeds and fertilizers is guaranteed, thanks to an independent coulter with a parallelogram attachment and two support-collecting wheels, and rolling wheels with atmospheric pressure tires allow you to work in any conditions, including in conditions of high soil humidity. The design of the stand of the sowing complex with seeding in the anchor coulter on a parallelogram also guarantees a high ability to pass crop residues. This sowing complex is designed for lowercase sowing of grain, leguminous and small-seeded crops on a processed or minimally processed background.

The complex is used in all agroclimatic zones, including those subject to wind and water erosion, on all types of soils, including stony ones. Effective use of the complex in the system of traditional and minimal (Mini-till).

The use of the complex provides:

- use in extreme agroclimatic conditions;

- pneumatic seeding of grain and leguminous crops, individual rolling when seeding in an anchor coulter;

- joint application of dry granular mineral fertilizers;

- application of liquid fertilizers (such as CAS) - as an additional option.

The main distinguishing feature of seeding complexes with seeding in an anchor coulter is a high service life.

High maneuverability, transport speed and mobility make it possible to use sowing complexes in remote fields of small size, reducing energy consumption and increasing productivity in relation to traditional sowing technologies.;

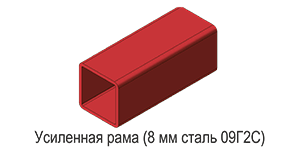

- Reinforced frame, rigid in all directions of traction application;

- The frame structure uses thick-walled profile pipes made of 09G2S steel, which is characterized by excellent weldability and increased strength;

- The rigid, yet light working part (frame with working elements) allows you to reduce the tractor's traction forces.;

- The installation of the transport frame made it possible to place the anchor posts in four rows, which eliminated the clogging of the posts with plant and crop residues and allowed the use of a sowing complex with seeding in an anchor coulter in conditions of high humidity;

- The use of series-connected hydraulic cylinders ensures a uniform level of penetration, simplifies technological adjustment and reduces the load on the frame and working elements. This solution allows you to improve the quality of tillage and increase the service life of the sowing complex;

- Modern exclusive technologies such as HDTV surface hardening, electric spark alloying, etc. are used in the production of the frame and working elements of the complex.

|

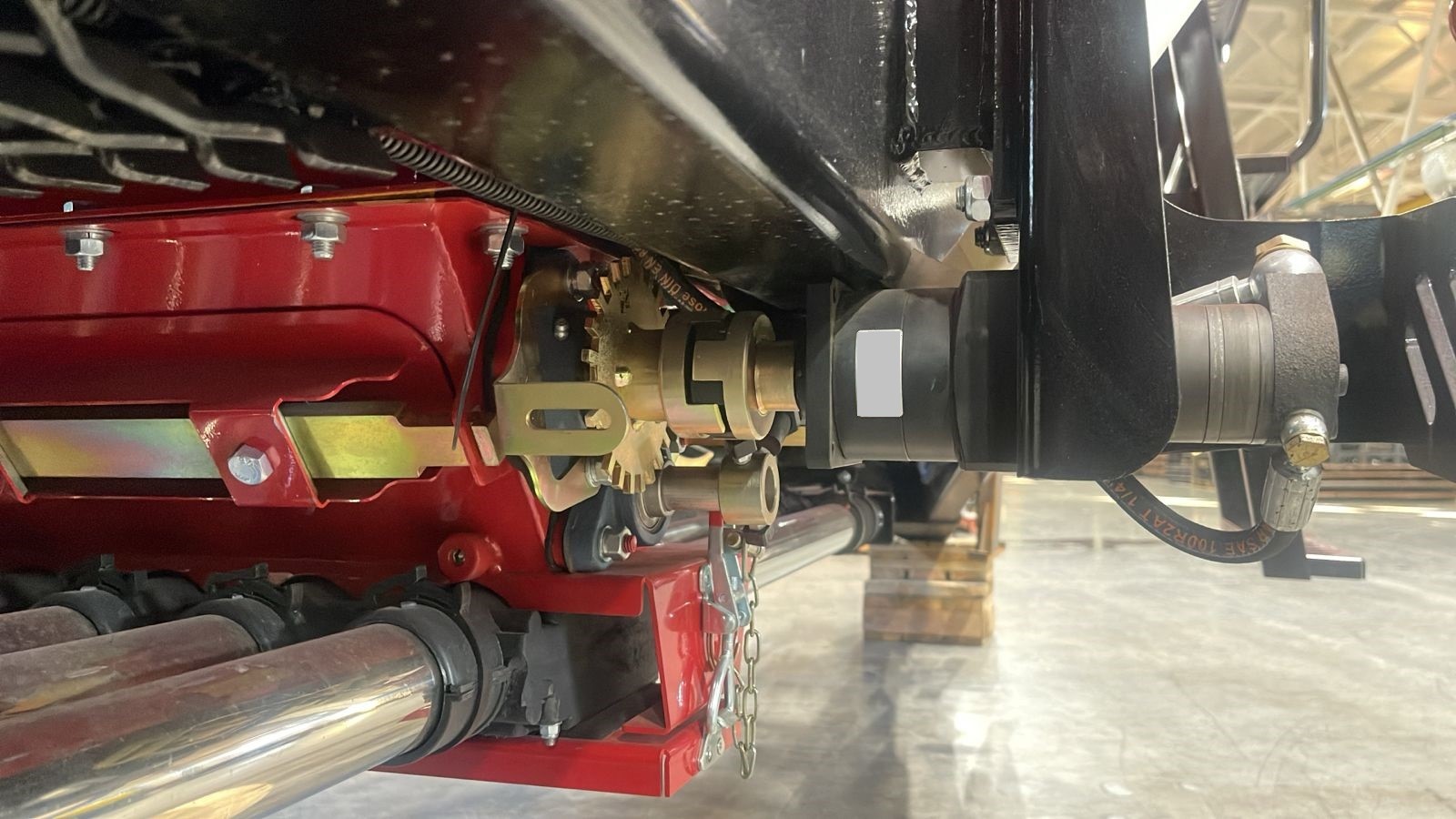

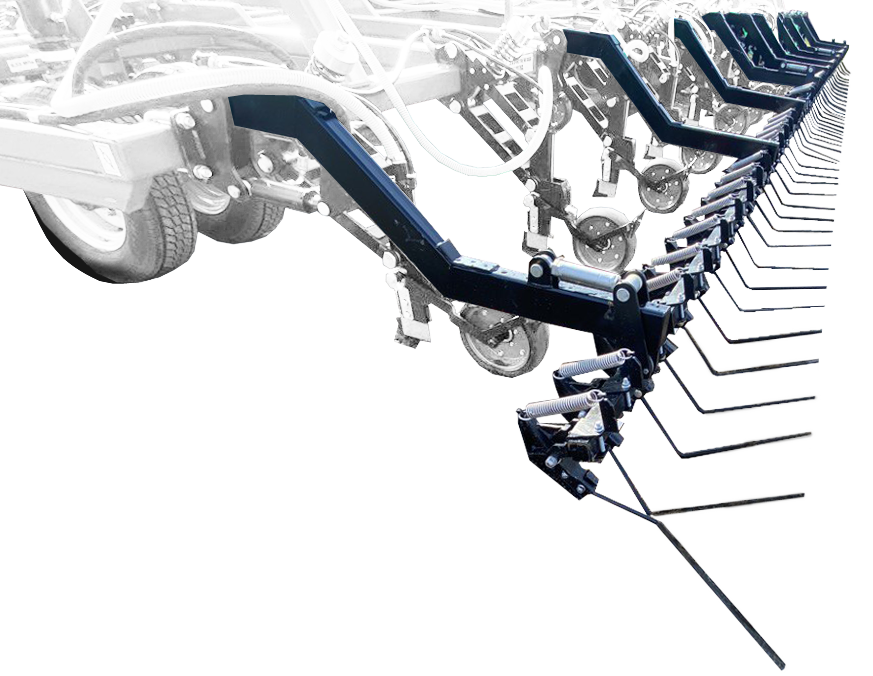

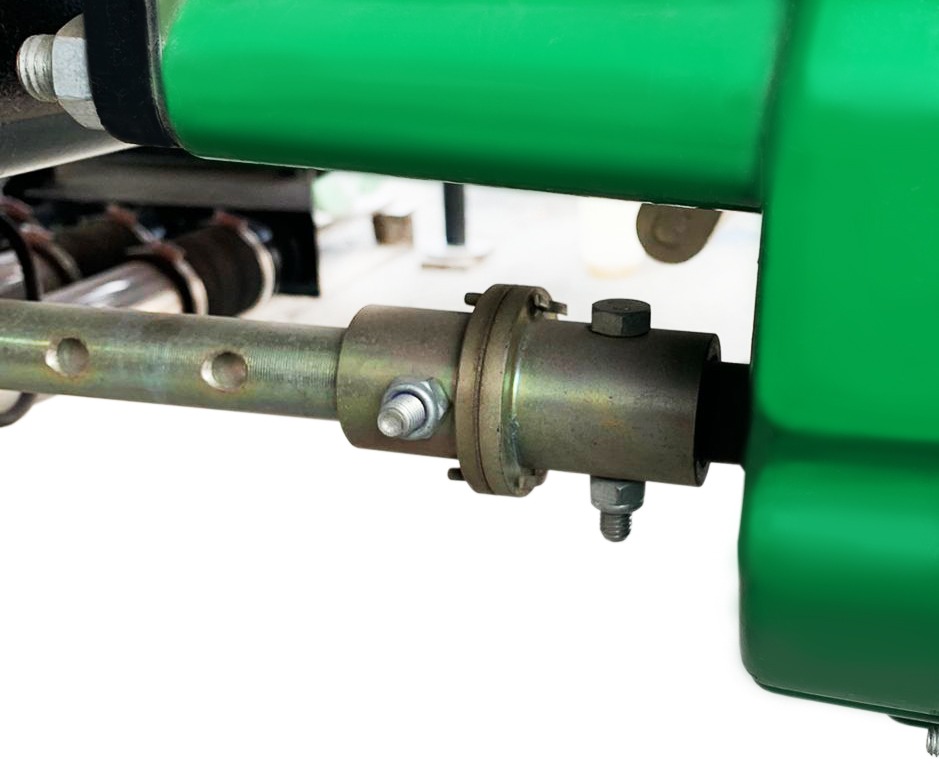

- an anchor coulter on a parallelogram hitch with spring adjustment of the cutting force into the soil;

- two support-collecting wheels with the ability to adjust the angle of attack;

- individual rolling wheel with the ability to adjust the rolling force.

- Easy-to-maintain seed dispensers are installed on the frame of the sowing complex, which distribute the seed material with high accuracy.

- The anchor coulter stand is made of steel 09G2S, the parallel connection is fixed with dry-slip bushings, which eliminates the maintenance of these components and increases the service life of the entire unit.;

- Thanks to the high ground clearance and the staggered arrangement of the anchor posts, the optimal passage of crop residues between the stands of the sowing complex is ensured;

- Anchor coulters with a thickness of 12 mm are installed on the complex, made of 65G steel with a hard alloy plate VK8 surfaced, with an individual rolling wheel with an atmospheric pressure tire;

- The anchor coulter consists of:

- The support-collecting wheels of the anchor coulter consist of reflecting discs and rotating support elements that reflect the soil flow, closing the seed furrow. Support-collecting wheels provide the necessary depth of the coulter at any speed of movement of the sowing complex, if necessary, it is possible to adjust the angle of attack of the support-collecting wheels.

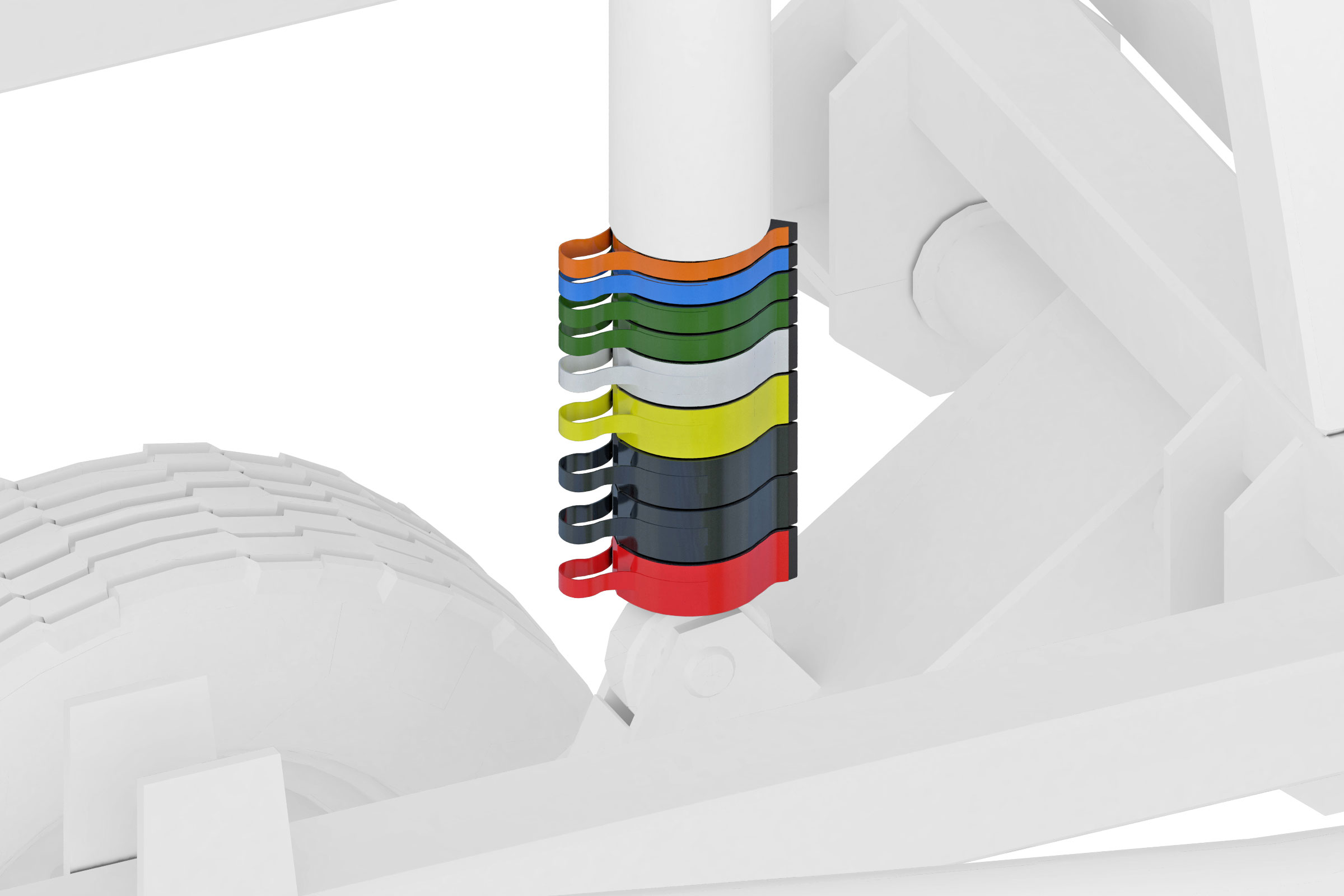

- Individual push-up wheels with adjustable force and bearings of the FKL brand (Serbia), which do not require maintenance, serve as an ideal mechanism for closing the seedbed.

-

The unit has the ability to move crop residues and soil from the seed row, which reduces the possibility of root diseases.;

-

All components of the unit, with the exception of bearings, hydraulic cylinders and tires, are manufactured at our factory, which greatly simplifies warranty and post-warranty maintenance of equipment.

- In the design of the support wheels, reinforced FKL bearings for agricultural purposes are used, which can withstand significant loads.

- The installation of an additional option - a liquid fertilizer application system-is provided due to the output of the feeder into the anchor.

- Installation of a harrow-leveller (basic equipment) with a hydraulic lifting/lowering mechanism is provided. The harrow-leveler smooths out the afterglow and creates an ideally even coating over the seeds.

|

The standard equipment of the APU series sowing complexes includes the installation of:

|

|

|

|

Pick-up wheels with a spherical pneumatic tire, 100 mm wide.

|

|

|

- Reinforced frame, rigid in all directions of traction application;

- The frame structure uses thick-walled profile pipes made of 09G2S steel, which is characterized by excellent weldability and increased strength;

- The rigid, yet light working part (frame with working elements) allows you to reduce the tractor's traction forces.;

- The installation of the transport frame made it possible to place the anchor posts in four rows, which eliminated the clogging of the posts with plant and crop residues and allowed the use of a sowing complex with seeding in an anchor coulter in conditions of high humidity;

-

- In order to ensure safe operation of the seed hopper, ladders and fences are installed, as well as a special anti-slip coating on the surface of the hopper;

|

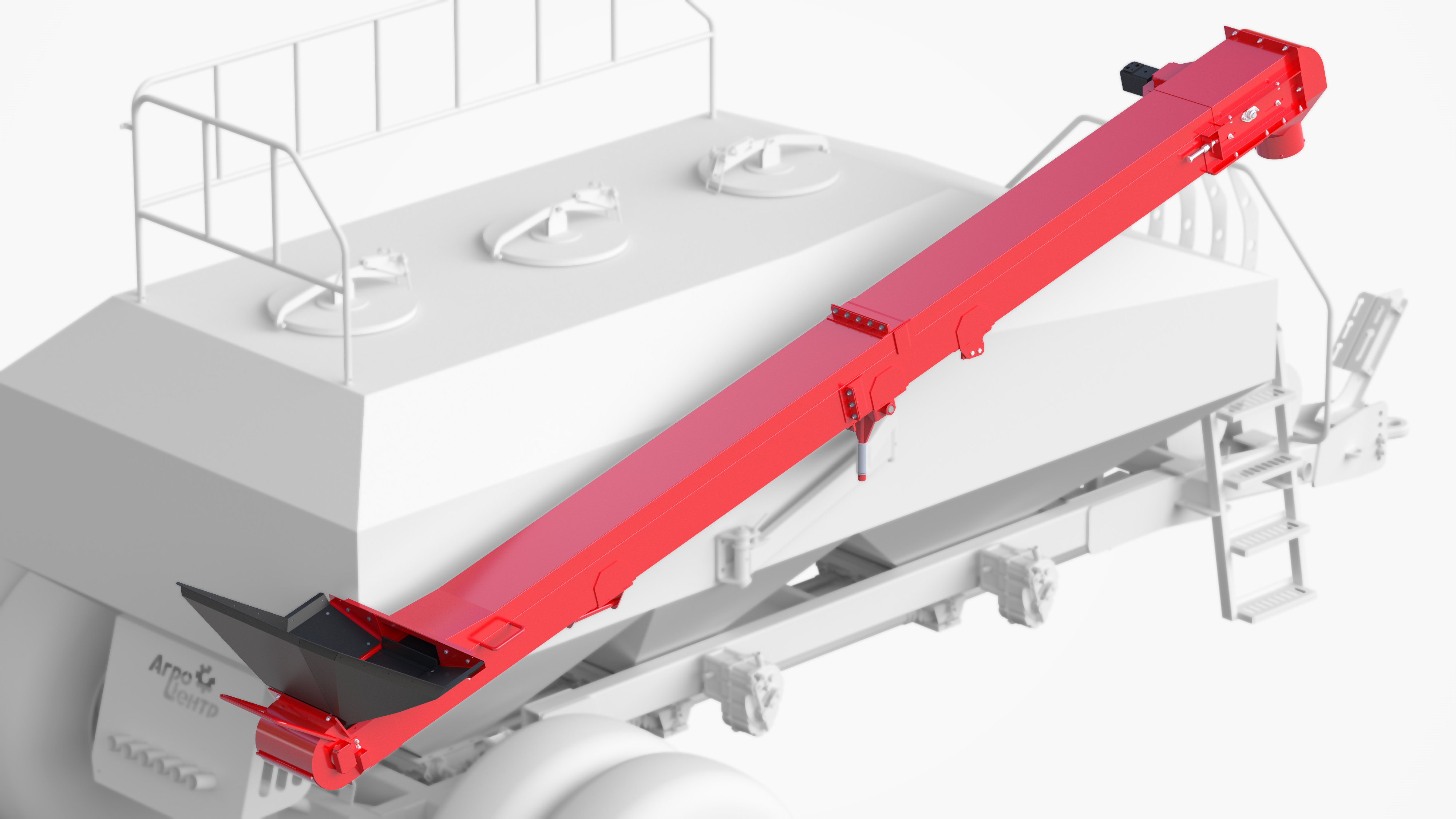

- For fast loading of seed material, a screw loader with LED lighting is installed, which allows loading in the dark, which allows you to operate the sowing complex in two shifts;

|

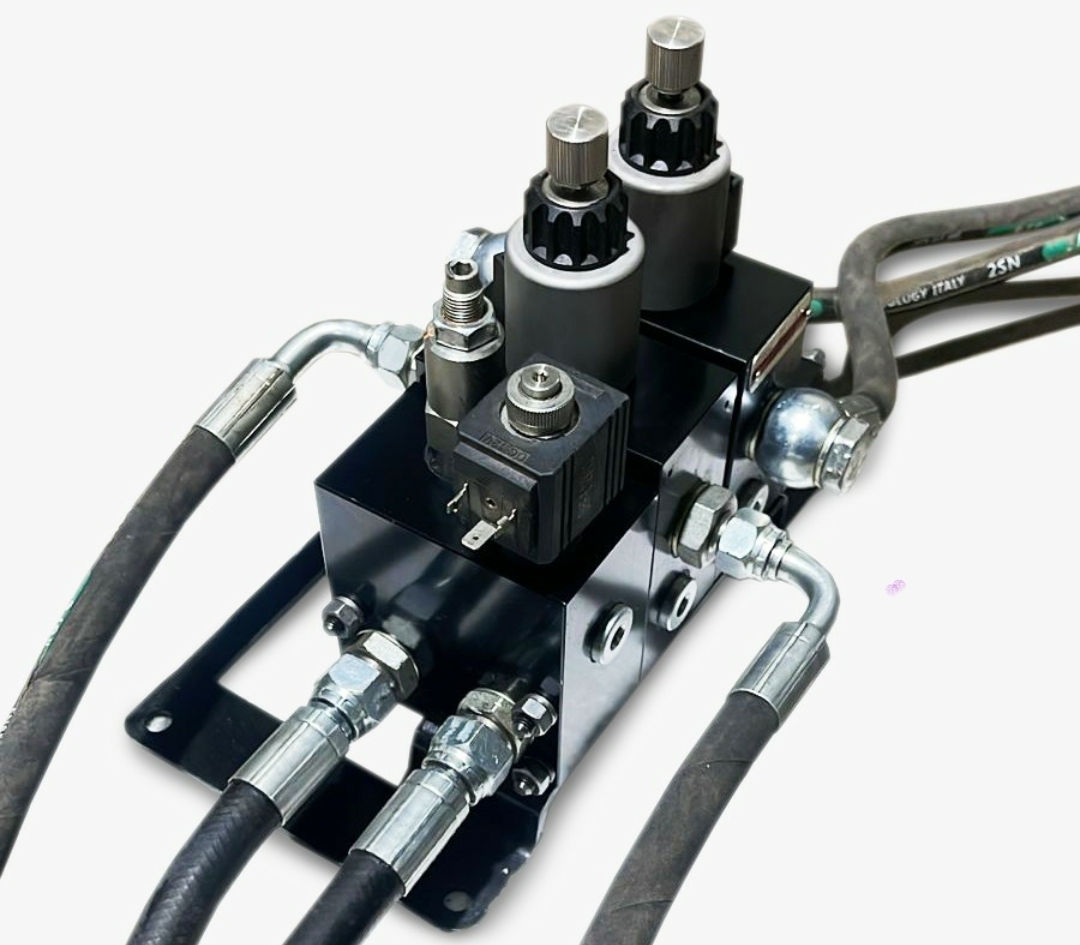

- Sowing complexes with seeding in a disc coulter are optionally equipped with a liquid fertilizer application system (CAS type) with a life pump driven by a gerotor hydraulic motor;

|

- The six-channel distribution of seed flow ensures accurate dosing across the entire coulter group and minimal injury to seed material.;

|

- The kinematic scheme for driving dispensers through a variator has a wide range of variations in the speed of rotation of the metering coils, which allows you to set seeding rates from 2.5 to 400 kg / ha.

|

- The CVT shaft is equipped with a bursting coupling to prevent breakage in the event of clogging of the dispenser coils.

- For applying liquid fertilizers, the sowing complex is additionally equipped with: a pipeline system, injectors or feeders, which are connected to the control unit installed on the hopper of the sowing complex with control from the agronavigator monitor installed in the tractor cab;

- Sowing complexes with seeding in an anchor coulter on a rack with a parallelogram attachment with two support-collecting wheels and an adjustable individual rolling wheel optionally equipped with a liquid fertilizer application system (CAS type) with a life pump driven by a gerotor hydraulic motor;

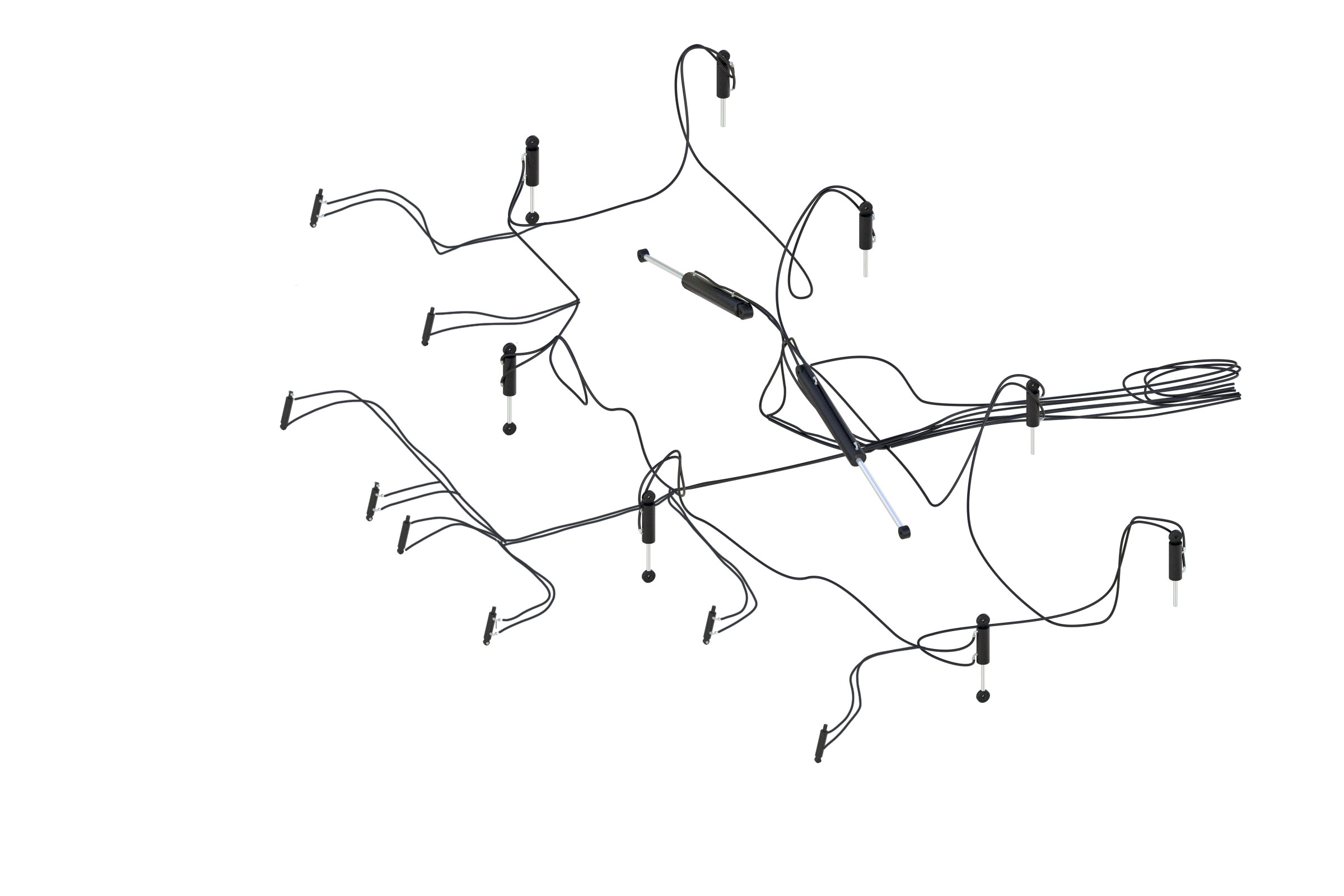

- The sowing complex is equipped with the SKIF (Radian Plant) seeding control system, which includes:

-

- hopper sensors (coupling start-up unit, data acquisition unit, metering shaft rotation sensors, fan, hopper filling sensor, hopper pressure sensor)

- sensors of the sowing part (sensor for clogging vas deferens, sensor for cultivator position).

- The specified rate of application of seeds and fertilizers is provided by the pressure in the hopper tanks. An overpressure monitoring sensor is installed in each tank to quickly monitor the tightness of hatches and the serviceability of other bunker elements. If the pressure in the hopper drops below the permissible limit, a warning signal lights up on the monitor.;

- Electronic seeding control system and on-board navigation system – monitoring the stability of the seeding complex and parallel driving based on GLONASS / GPS;

- The ability to easily reinstall and use the GLONASS/GPS on-board navigation system on sprayers and other agricultural machinery.

|

|

%20%20%20%20%20%20%D1%81%D1%84%D0%B5%D1%80%D0%B8%D1%87%D0%B5%D1%81%D0%BA%D0%BE%D0%B9%20%D1%84%D0%BE%D1%80%D0%BC%D1%8B%20%D1%88%D0%B8%D1%80%D0%B8%D0%BD%D0%BE%D0%B9%20100%D0%BC%D0%BC.png)

.jpg)