FEAT Sowing Complexes with seed placement into the shovel

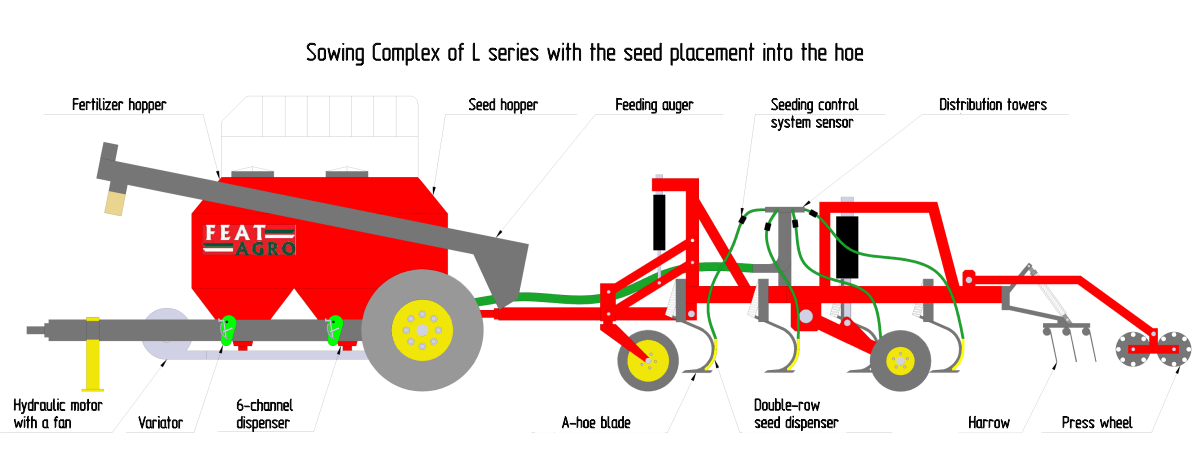

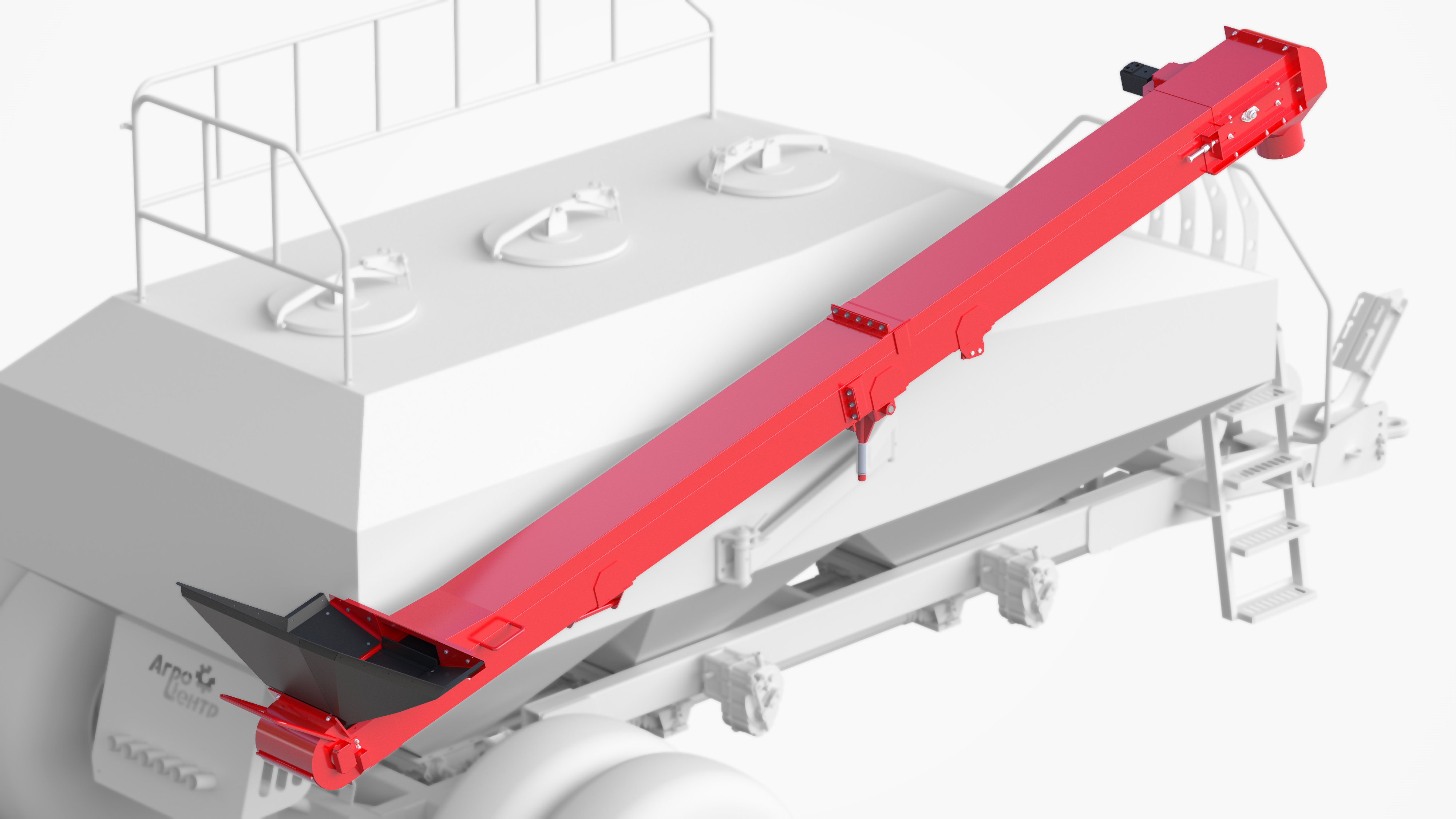

The combined sowing complex “FEAT” with the seed placement into the shovel is designed for band planting of cereal, legume and small-seeded crops simultaneously with granulated fertilizers on the untreated background and soil handling in the cultivation mode: pre-sowing, autumn and fallow cultivation.

The complex is used in all agro-climatic zones, including those ones exposed to wind and water erosion, on all soil types, except for stony grounds. The application of the complex in the minimal tillage system is effective.

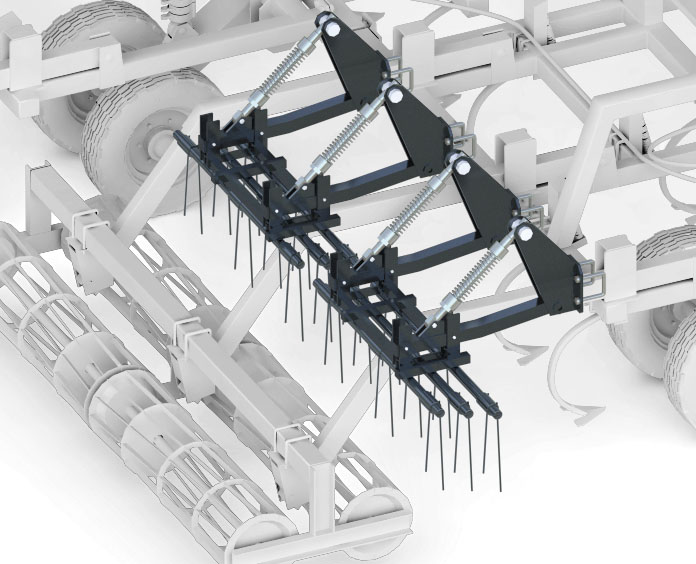

The cultivator part of the sowing complex is equipped with five rows of tines with a flat shovel. The double spring creates force on the shovel equal to 1000N (120 kg), which allows to treat soil properly at a given depth and ensures 100% weed cutting, while preventing from the unit damages when increasing force on the shovel more than the nominal one.

The machine seed loading, electronic quality control of the seeding machine functioning and parallel driving system allow to carry out planting confidently at any time of the day, in case of any dust content and to maintain the complex by one tractor operator only. Upon completion of the planting season, the complex is easily transformed into a cultivator, which can be used for cultivation of fallow lands and the basic fall cultivation.

Sound “PRO” arguments for the KPK complex of the FEAT series with seed placement into the shovel:

A wide product range with the operating width of 5.4; 7.2; 8.5; 9.9; 10.8 meters, which allows to load the entire line of tractors used in the agricultural production in the optimal way;

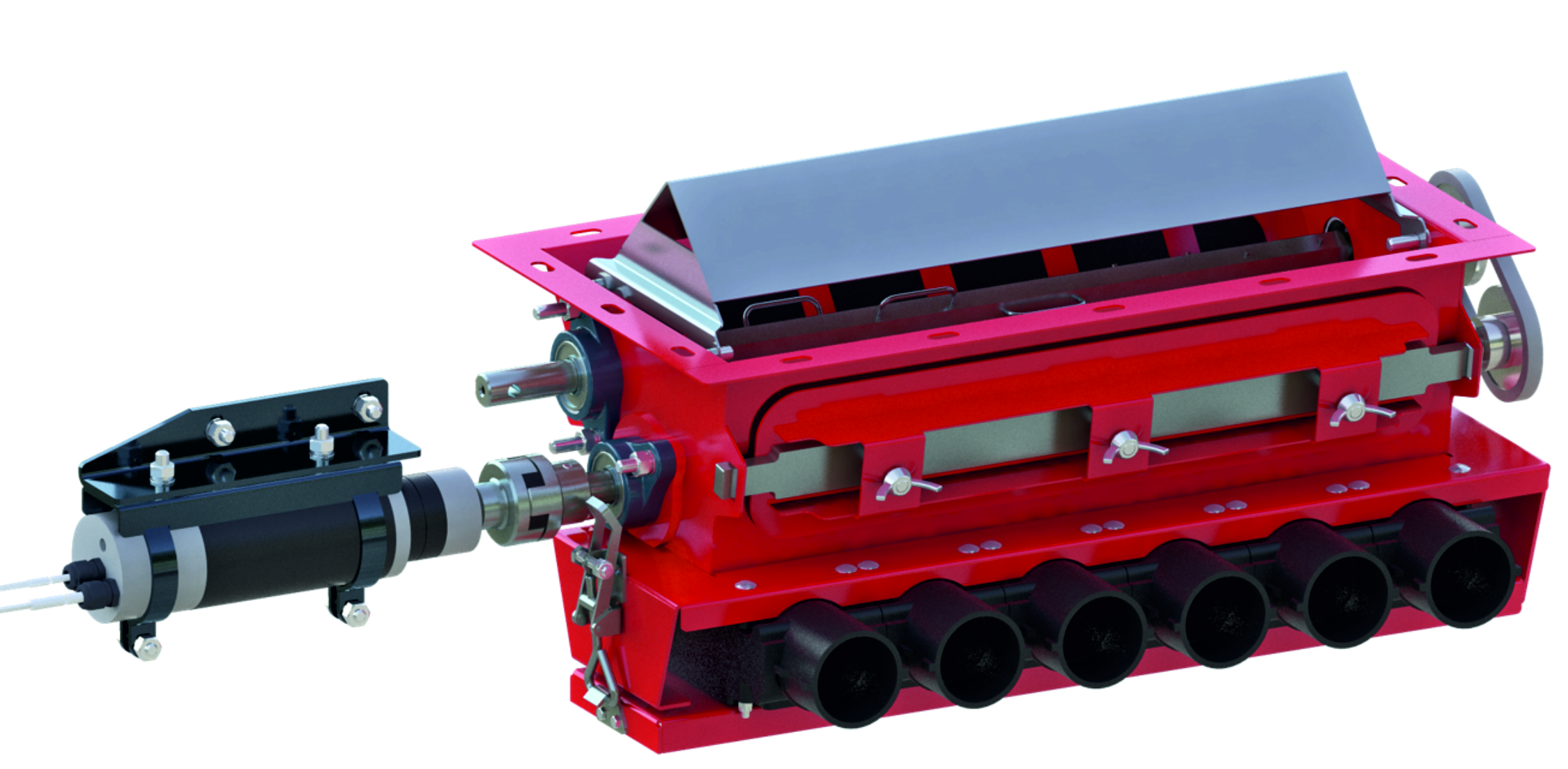

The six-channel distribution of the seed flow – dosing accuracy in the whole coulter group and minimum damages to the seed materials;

The operative parts (tines, shovels) and springs are made of high-carbon spring steels, using the advanced methods of thermal treatment and hardening;

The complex is used in all agro-climatic zones, including those ones exposed to wind and water erosion, on all soil types, except for stony grounds. The application of the complex in the minimal tillage system is effective;

The application of the complex provides:

- field leveling;

- seedbed leveling;

- mechanical weeding;

- soil mulch formation;

- pneumatic planting of cereal and grain legume crops, continuous ramming when sowing into the shovel;

- application of granulated fertilizers together with the seeds;

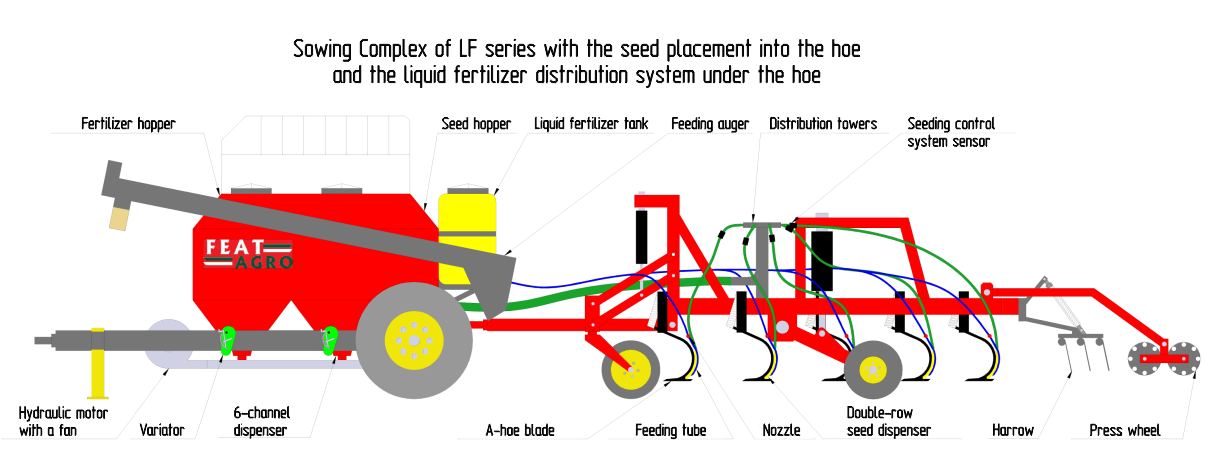

- application of liquid fertilizers, when installing the liquid fertilizer distribution system LFDS (option) on the sowing complex;

- when operating in the cultivation mode, in case of autumn treatment – destruction of lower compacted soil layers;

The cultivator tines with the operating parts are installed in five rows at a pitch of 232 mm, the springs create the operating force of 1000N (120 kg) at least and serve to protect from damages to the unit when the load on the tines is higher than the permissible one, and to reduce the traction force;

A multiple number of the cultivator tines and disc coulters allow sowing both into the shovel and (in case of some re-equipment) into the disc coulter;

The reinforced frame is rigid in all directions of application of the traction force;

The frame structure provides for thick-walled non-circular pipes from 09G2S steel, differing in excellent weldability and increased strength;

The original design of the cultivator tine, which allows the all-welded frame to have continuous supporting beams with a width of 100 mm at least, at a pitch of 232 mm between the tines, makes the frame more rigid and light enough;

The installation of the transport frame enabled placement of the cultivator tines in five rows, which excluded clogging of the cultivator part with plant and stubble residues;

The extended basis of the cultivator increases the accuracy of the operating depth and improves the quality of the field surface leveling;

The cultivator part of the sowing complex can be used as an independent tillage unit – a cultivator of the PK series;

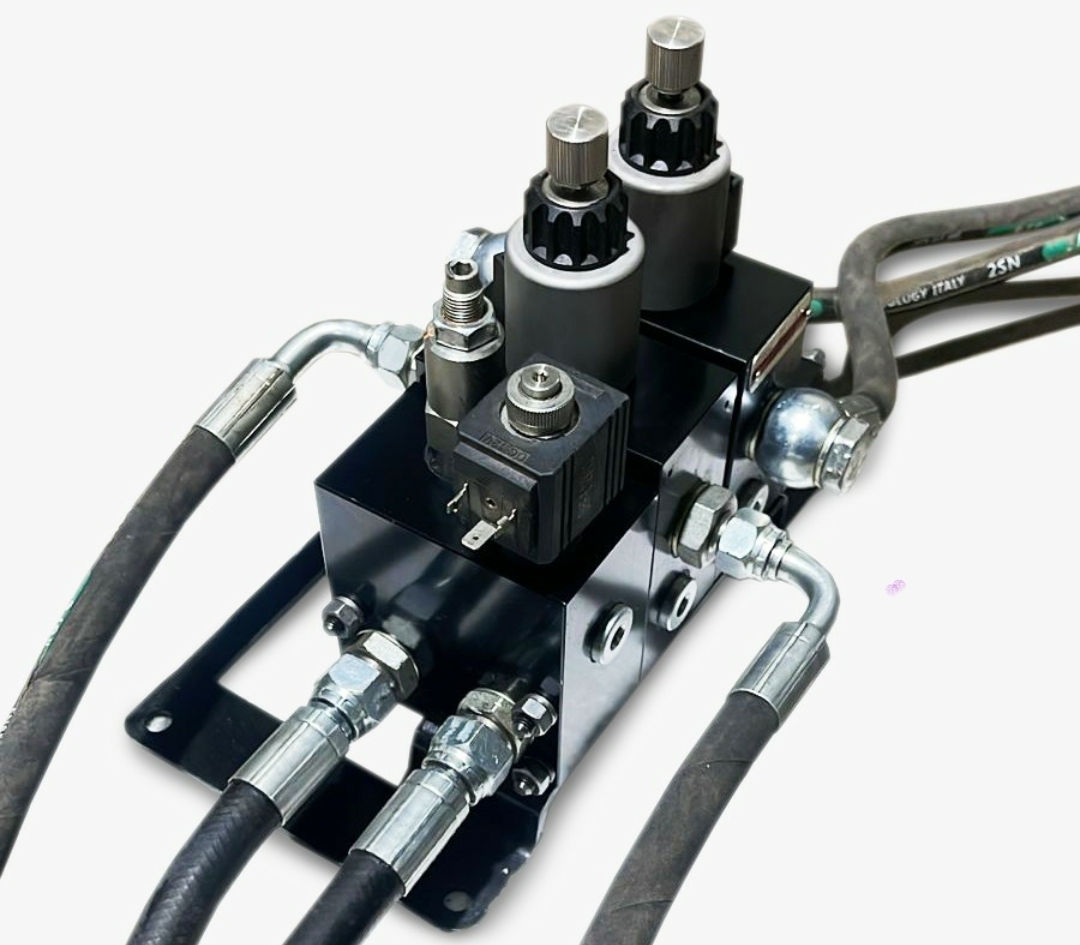

The application of hydraulic cylinders in the series connection reduced the load on the frames and operating parts of the seeding complex and simplified its engineering adjustment, which improves the soil cultivation quality and increases the service life of the assembly units and the sowing complex in general;

All assembly units of the complex, except for bearings, hydraulic cylinders and tires, are manufactured at our plant, which fact essentially simplifies the warranty and post-warranty maintenance of the machinery;

When manufacturing the cultivator, up-to-date exclusive technologies such as high-frequency current surface hardening, electro-spark alloying etc. are used;

The application in the design of modern polymeric and composite materials, production of dispensers from stainless steel and polymeric materials make the unit reliable and durable even when working with mineral fertilizers;

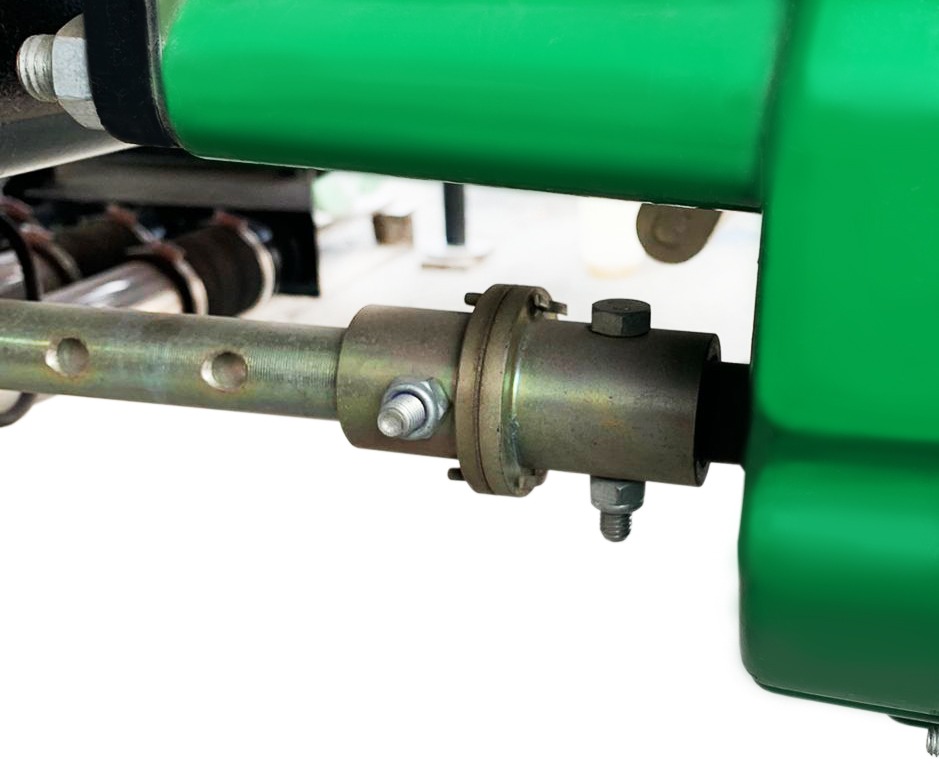

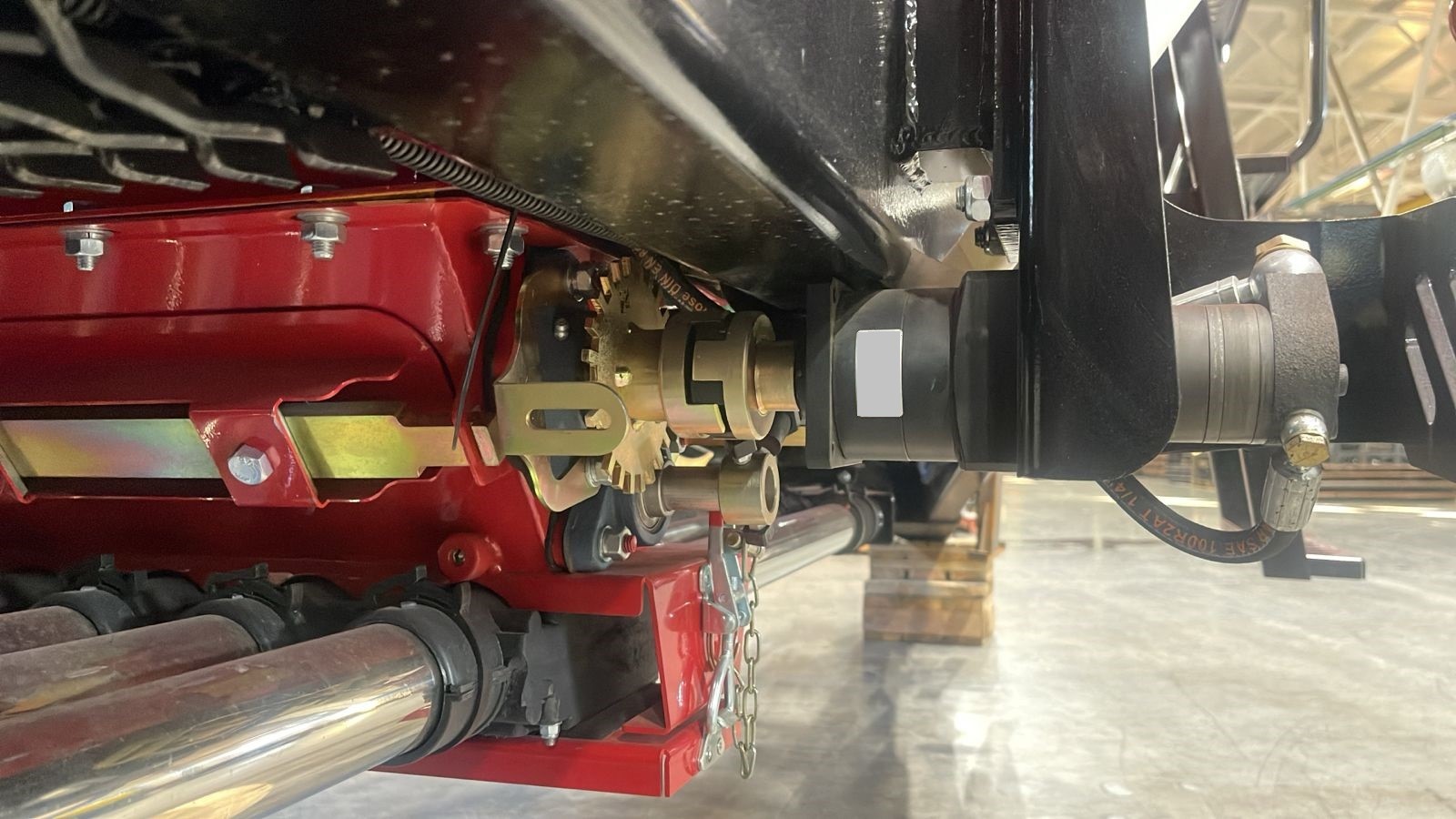

The kinematic scheme of the dispenser drive through the variator has a wide range of variation in the rotational speed of the dispensing coils, which allows setting of the seeding rates from 2,5 to 400 kg/ha;

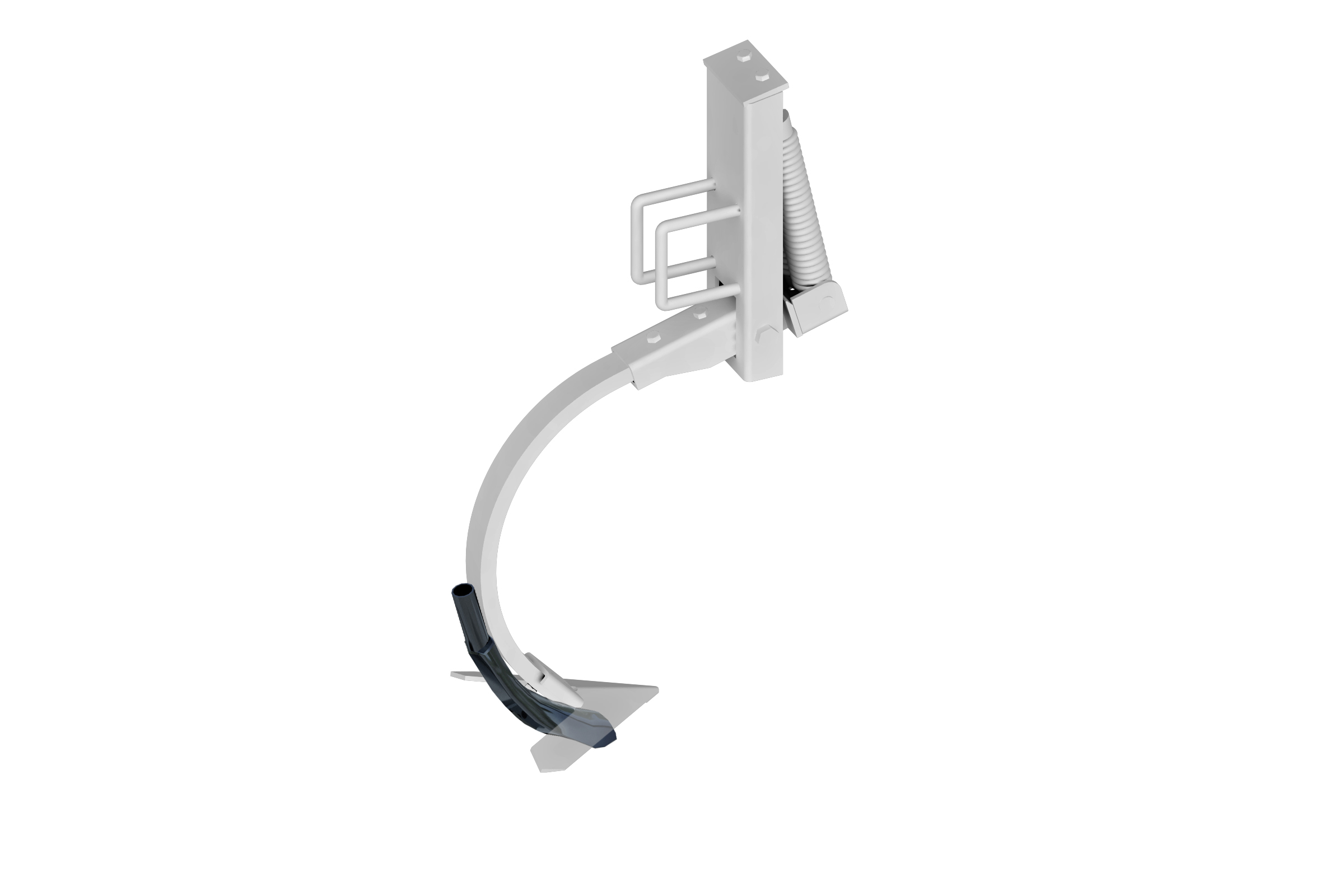

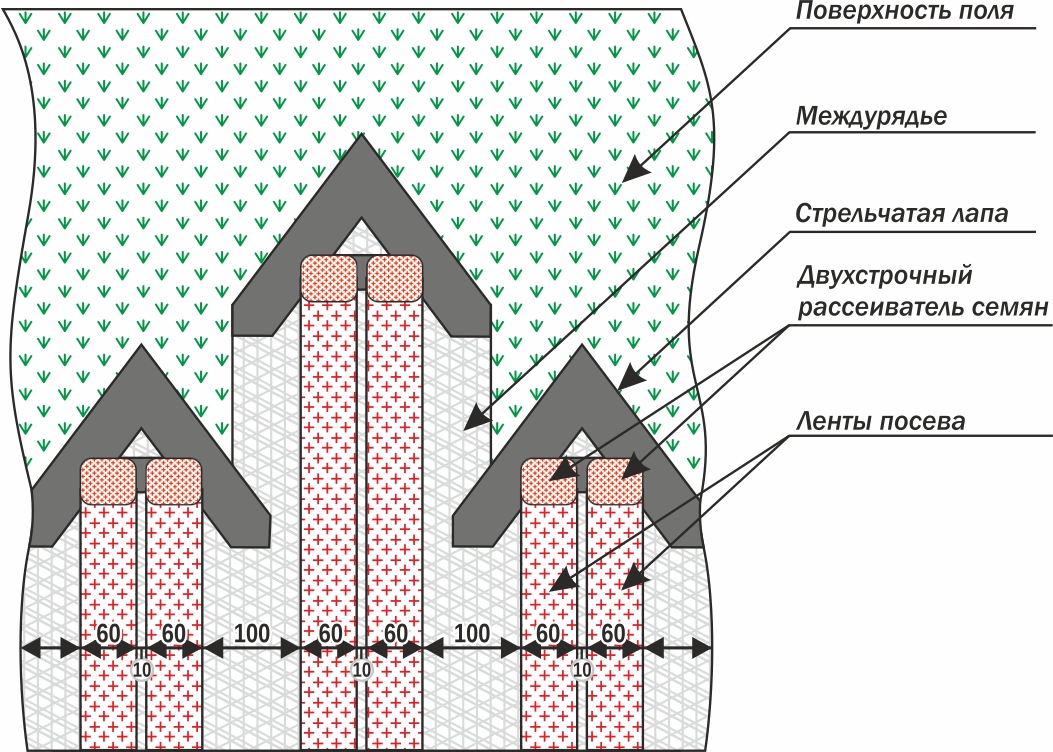

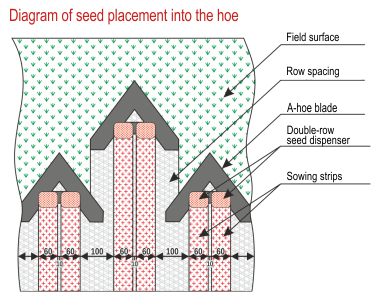

When the seeding complex is moving in the sowing mode: the flat shovels cut off weeds and loosen the soil as well as create a dense seedbed, which lays down seeds and fertilizers into two bands using scatterers (the distance between the bands is 1 cm) up to a depth of the shovel treatment. The double-row spring harrow aligns the field surface and distributes the stubble remains evenly, the double-row pipe rollers roll down and level the surface, as well as the hopper supplies fertilizers and seeds in doses to the scatterers through the pneumatic system. The treatment is carried out up to a depth of 3 ... 10 cm;

The operating depth is regulated with the help of firmly fixed clips on the hydraulic cylinders of serial connection at a pitch of 1 cm – guaranteed preservation of the set adjustments;

The required application rate of the seeds and fertilizers ensures pressure in the hopper tanks. To monitor tightness of the hatches and serviceability of the other elements of the hopper, there is an excess pressure control sensor installed in each tank. When the pressure in the hopper is reduced lower than the permissible one, a warning signal lights up on the monitor;

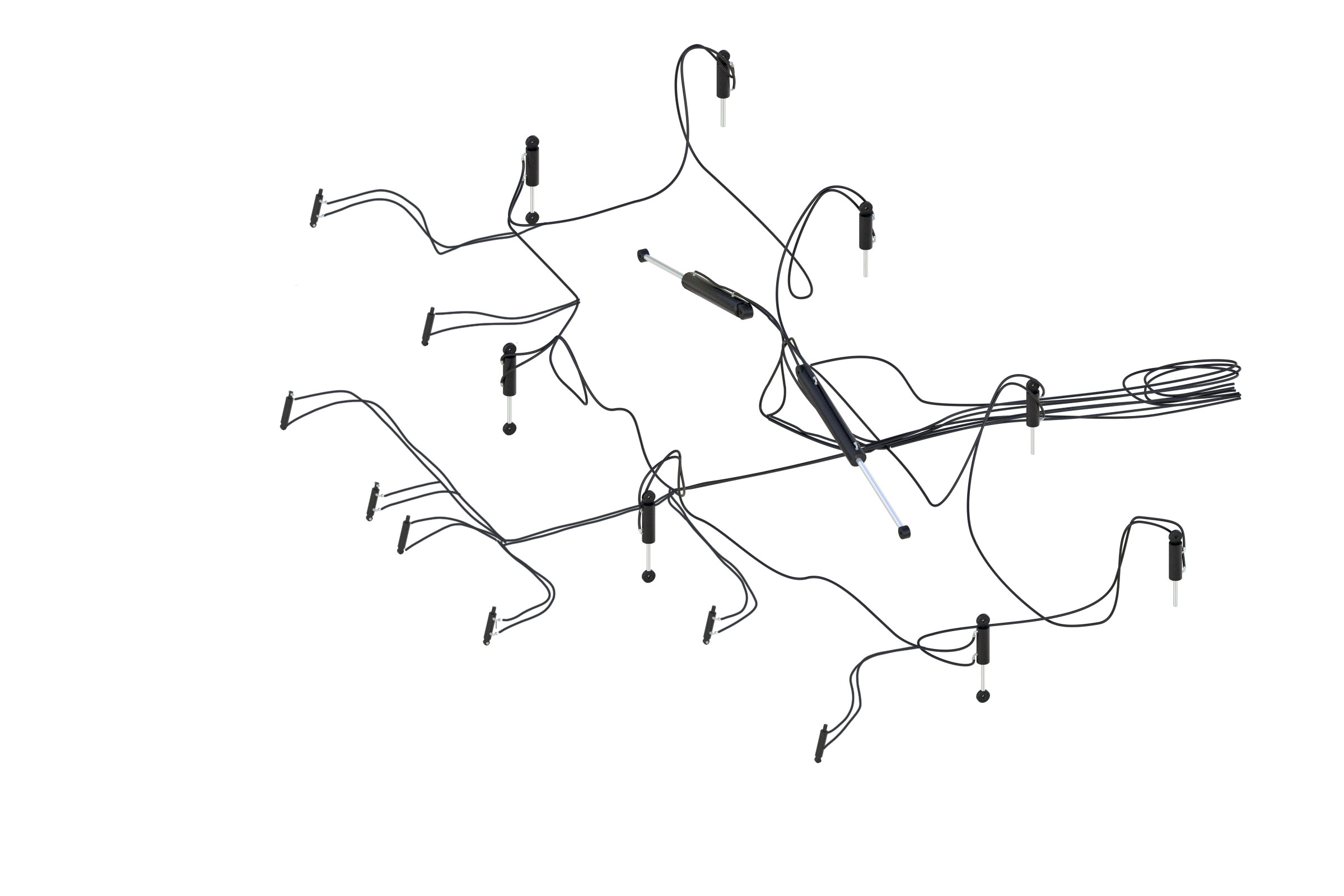

The sowing complex is equipped with a control system for the sowing parameters: electromagnetic coupling, position of the cultivator, functioning of dispensers, fan, level of the seeds and fertilizers, pressure in the hopper, clogging of the seed drill tubes and the parallel driving system. The high maneuverability, transport speed and mobility make it possible to use the sowing complexes in remote fields of small dimensions, while reducing the energy consumption and increasing productivity in relation to the traditional sowing technologies;

The sowing electronic control system and the board navigation complex – monitoring of the stable functioning of the sowing complex and parallel driving on the basis of GLONASS/GPS – are included into the scope of supply;

The opportunity of easy reinstallation and the use of GLONASS/GPS board navigation system on sprayers and other agricultural machinery;

Two location variants of the hoppers which are easily detachable from the frame – posterior-mounted or anterior-mounted one with the volume of 6.8 m3 (factory package) or with the volume of 10,0 m3 (optionally).

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

- датчики бункера (блок запуска муфты, блок сбора данных, датчики вращения вала дозатора, вентилятора, датчик наполнения бункера, датчик давления бункера) - датчики высевающей части (датчик забивания семяпроводов, датчик положения культиватора). |

|

||

|

|

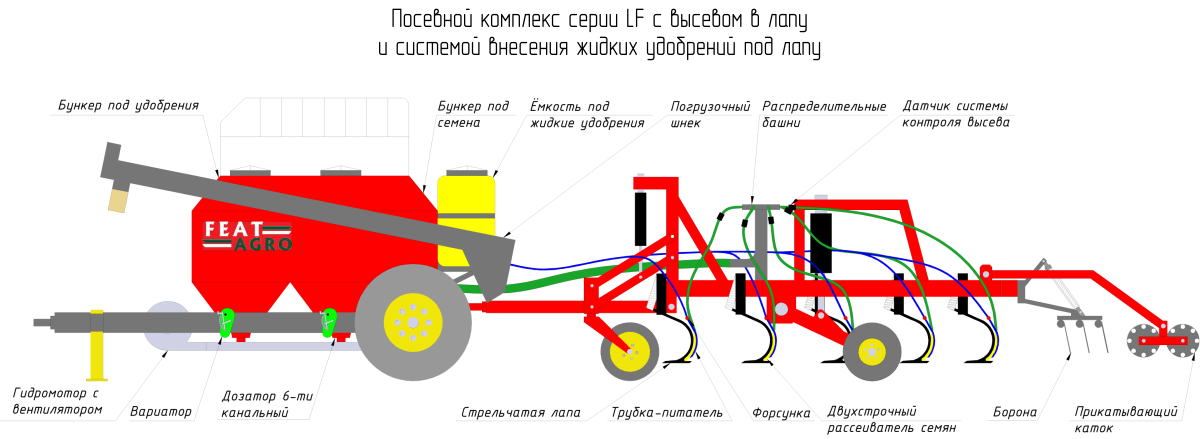

Внесение жидких удобрений одновременно с посевом сельскохозяйственных культур посевными комплексами серии L может осуществляться двумя способами:

1. Бункер посевного комплекса опционально оснащается:

- ёмкостью объёмом 2 м.куб. под жидкие удобрения (типа КАС);

- приводом жидкостной помпы от героторного гидромотора;

- блоком программного управления выливом жидких удобрений

Высевающая часть посевного комплекса дополнительно оснащается:

- системой трубопроводов, форсунок и питателей.

2. Посевные комплексы серии L для внесения жидких удобрений агрегатируются с автоматической системой внесения жидких удобрений "Спутник-4000" или "Спутник-6000"

Высевающая часть посевного комплекса дополнительно оснащается:

- системой трубопроводов, форсунок и питателей

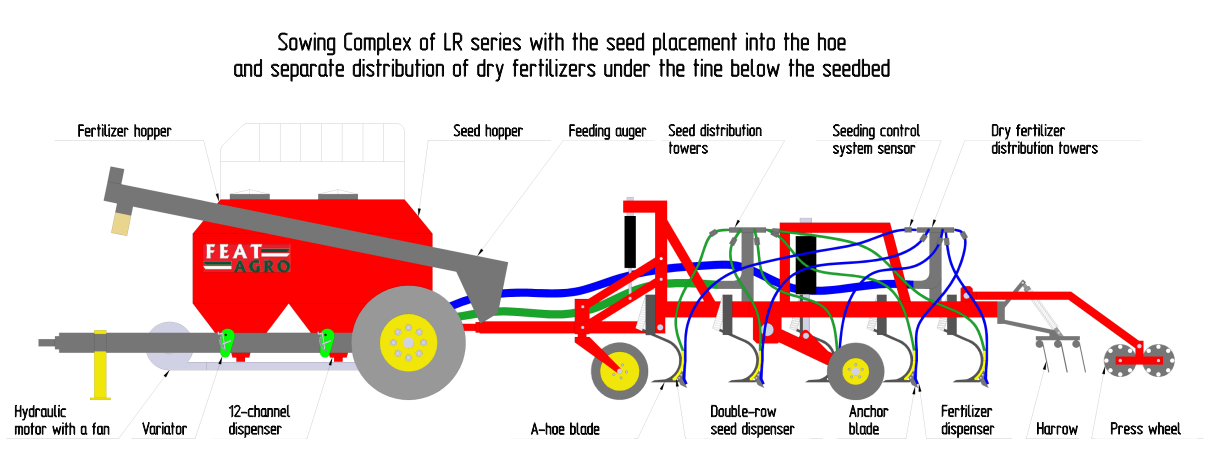

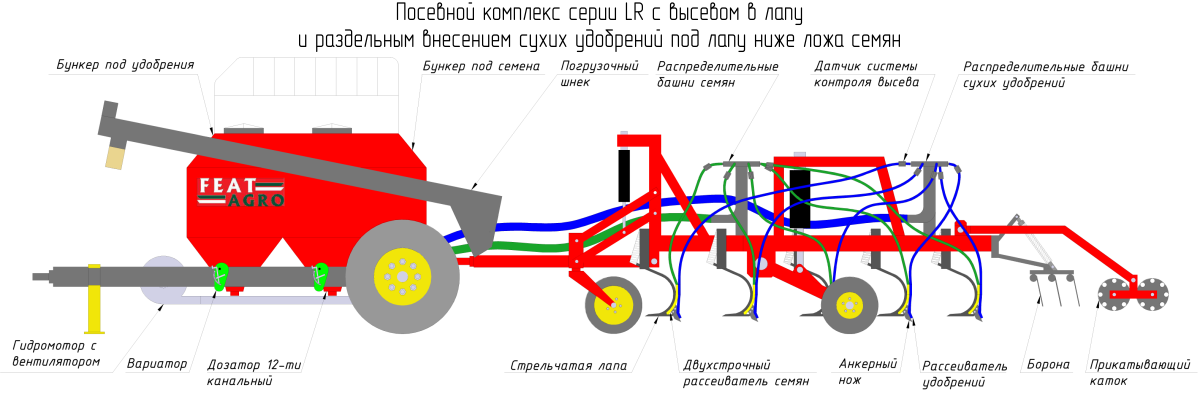

Система раздельного внесения сухих гранулированных удобрений (R) позволяет разделить потоки посева сельскохозяйственных культур и внесения удобрений на разную глубину благодаря:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Parameter name |

L-5400 |

|

|

|

|

|

|

|

|

5,4 |

7,2 |

8,1 |

9,9 |

10,8 |

12,5 |

|

|

|

5,4 |

7,2 |

8,5 |

9,6 |

10,8 |

12 |

|

|

|

24 |

32 |

36 |

42 |

48 |

54 |

|

|

|

260 |

||||||

|

|

23.5 |

||||||

|

|

5-8/5-6 |

||||||

|

|

2,5-400/35-400 |

||||||

|

|

|

||||||

|

|

|

||||||

|

|

|

14000 |

14000 |

14000 |

14000 |

14000 |

14000 |

|

|

5500 |

7200 |

8700 |

10000 |

11000 |

12200 |

|

|

|

3800 |

3800 |

3800 |

3800 |

3800 |

3800 |

|

|

|

length |

14000 |

14000 |

14000 |

14000 |

14000 |

14000 |

|

|

5500 |

5520 |

5520 |

5520 |

5520 |

5520 |

|

|

|

3800 |

3800 |

3800 |

4200 |

4400 |

5050 |

|

|

|

5000 |

6500 |

7300 |

8100 |

9000 |

10000 |

|

|

|

4500 | ||||||

|

|

7 |

||||||

|

|

1 |

||||||

|

|

200-280 4 |

280-300 5 |

300-350 6 |

350-400 7 |

400-420 8 |

420-450 9 |

|

.png)