Cultivators of PK series

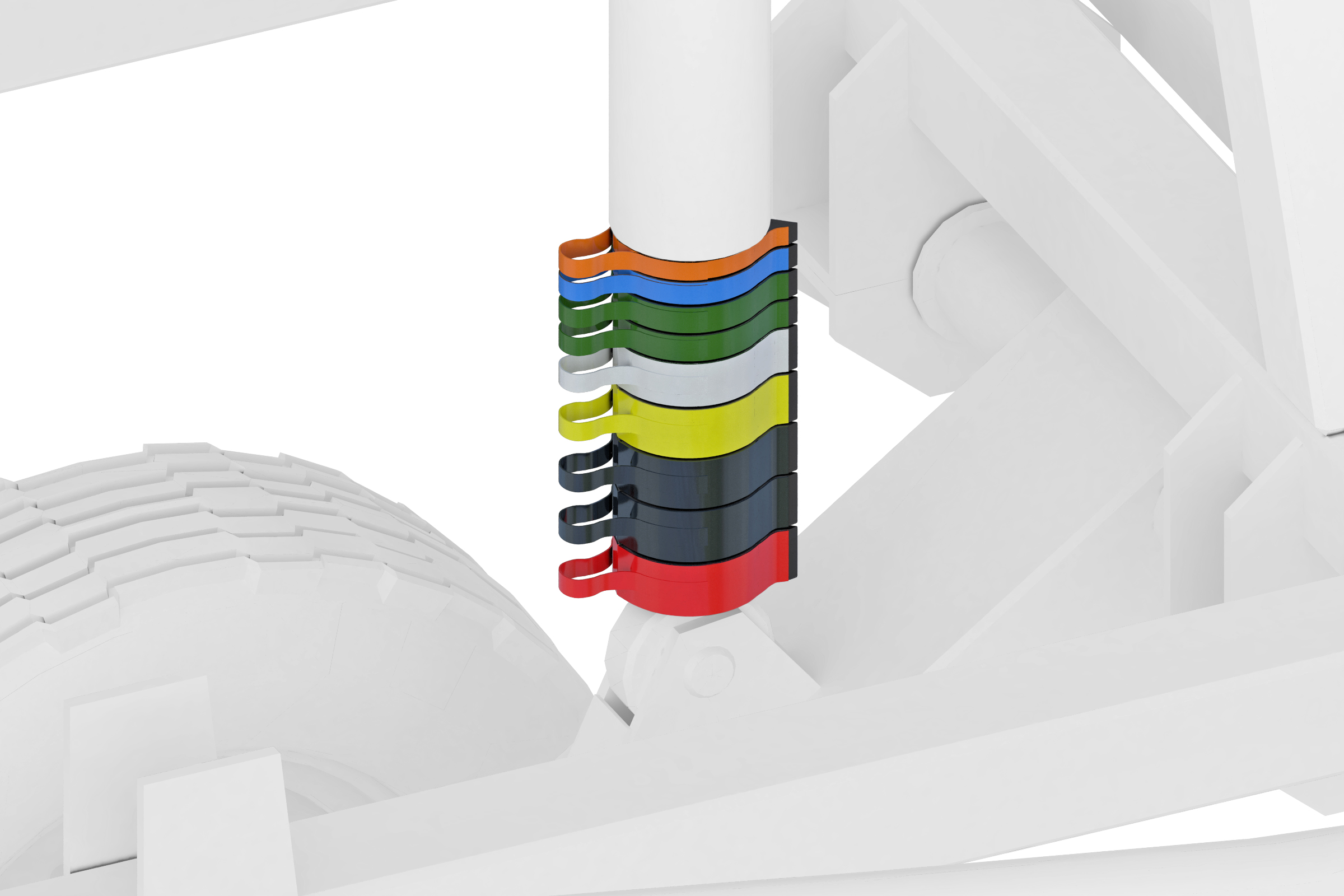

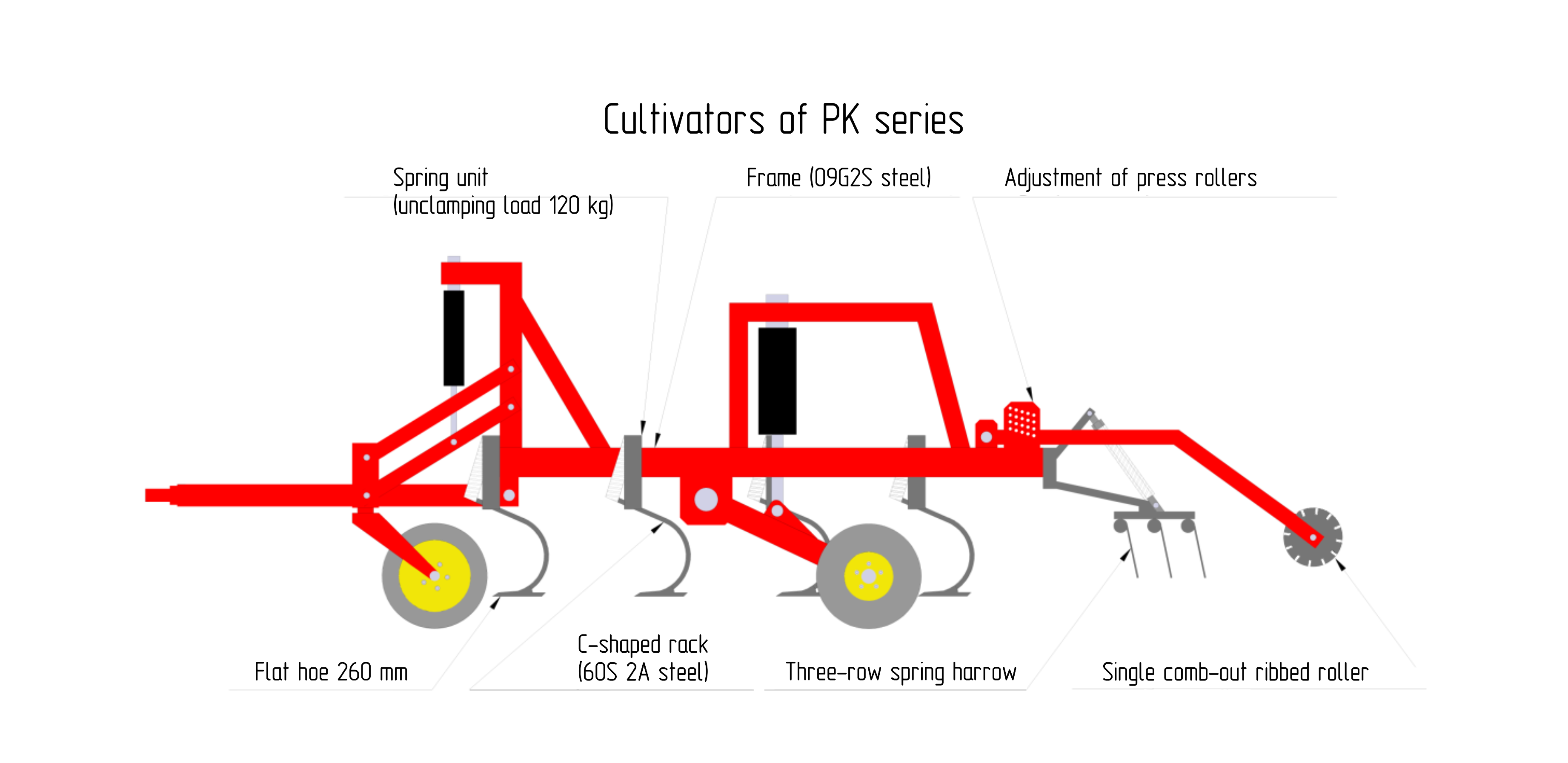

- the first five rows are the tines with hoe blades 260 mm wide, The double spring creates force on the shovel equal to 1000N (120 kg), which allows to treat soil properly at a given depth and ensures 100% weed cutting,

thereby preventing from the unit breakage in case of increasing the force on the blade higher than the nominal one;

-

the sixth row is intended for a harrow with the double spring teeth 400 mm high and the tooth spacing of 86 mm;

-

the seventh row is represented with combing out, press wheel or combined rollers.The structure of the cultivator frame and the set of adjustments allow this unit to work, depending on the agrotechnical tasks assigned to it and the weather conditions, with various basic options and without them, namely:in case of high humidity or autumn soil slitting with the chisel, the cultivator can work without the unit of spring harrows and free of the rollers, or the rollers just roll passively, while the cultivator itself is supported by a group of support (transport) wheels;in the second variant, the cultivator can work with any working and basic options, being supported by the front support (transport) wheels and the rear rollers. In this case, the rear support (transport) wheels are lifted up. It makes it possible to use the function of the spring harrows and the combing out, press wheel or combined rollers to the maximum extent.

-

Sound “PRO” arguments for the cultivators of PK series:• Extended product range with the operating width of 3,6; 5,7; 7,2; 8,5; 9,9; 10,8; 12,0 meters, which allows to load the entire line of tractors used in the agricultural production in the optimal way;• PK cultivators are used in all agro-climatic zones, including those ones exposed to wind and water erosion, on all soil types, except for stony grounds. The application of the cultivator for the basic and pre-sowing treatment in the no-till system is effective;• They are used in the autumn (underwinter) soil treatment completed with a chisel (included to the kit of spare parts and accessories);

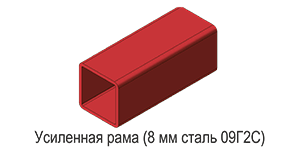

- Thick-walled profile pipes of various cross-sections with a wall thickness from 6 mm to 16 mm, steel 09G2S;

- The extended cultivator base increases the accuracy of the processing depth and improves the quality of field surface leveling;

- The use of serial-connected hydraulic cylinders has reduced the load on the frames and working bodies of the cultivator and simplified the technological adjustment of the cultivator, which improves the quality of soil cultivation and increases the service life of the units and the cultivator as a whole;

- The processing depth is adjusted by rigidly fixed clips on the serial-connected hydraulic cylinders with a step of 1 cm - guaranteed preservation of the set settings;

- The universal base of the PK series cultivators with D and L series seeding complexes allows you to retrofit cultivators into seeding complexes with both paw seeding and disc coulter seeding;

- Cast earring made of high-strength steel;

- The cultivator frame has 3 support points (front support wheels, transport wheels, rolling roller);

- Working bodies (racks, legs, chisel) are made of high-carbon spring steels, using modern methods of heat treatment and hardening;

- Cultivator racks with working bodies are installed in five rows with a pitch of 232 mm, springs create a working force of at least 1000N (120 kg), serve to protect against breakdowns of the unit, when the load on the racks is higher than permissible and reduce traction;

- All components of the unit, with the exception of bearings, hydraulic cylinders and tires, are manufactured at our factory, which greatly simplifies warranty and post-warranty maintenance of equipment.

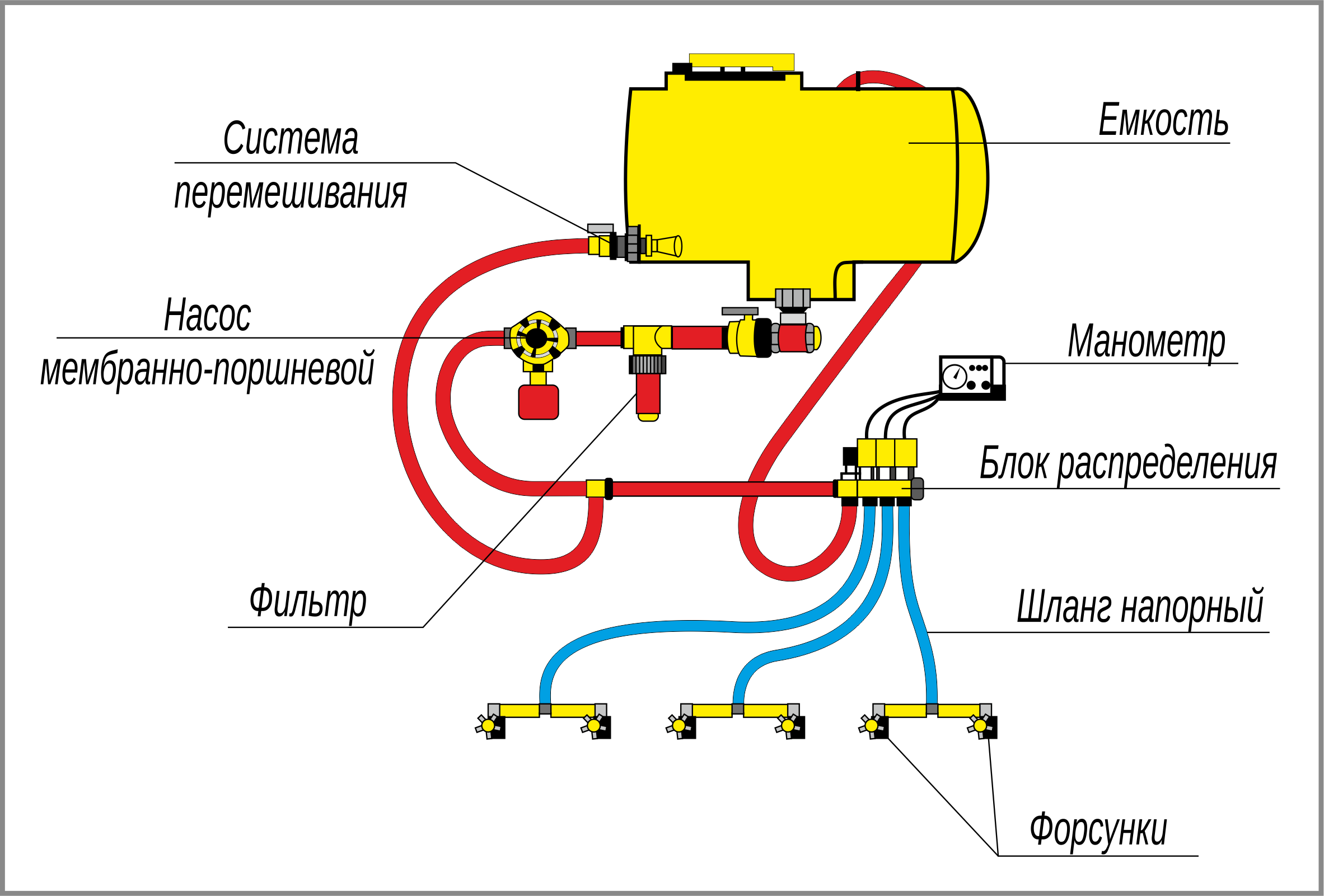

- Safety margin for load capacity, allows installation on the cultivator of the SVZHU liquid fertilizer application system, on any model of the cultivator there are connecting elements that allow the installation of this system.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Трехрядная борона с зубом высотой 400 мм и шагом 516 (86) мм, диаметром зуба 10 мм и регулируемым углом атаки; | ||

|

|

Тандемный прикатывающий каток диаметром 360 мм с подшипником FKL (Сербия) с регулируемым давлением; | |

| Система индивидуального копирования и давления всей навесной части. | ||

|

Дополнительная опция: Одинарный вычесывающий ребристый каток; |

Запас прочности по грузоподъемности, позволяет установку на культиватор систему внесения жидких удобрений СВЖУ, на любой модели культиватора имеются присоединительные элементы, позволяющей установку данной системы.

|

Parameter name |

PK-360 |

PK-570 |

PK-720 |

PK-850 |

PK-990 |

PK-1080 |

PK-1200 |

|||

|

Operating width, m |

3,6 |

5,7 |

7,2 |

8,5 |

9,9 |

10,8 |

12 |

|||

|

Productivity per 1 hour of basic time (at the speed of 12 km/h) ha, not less than |

3,6 |

5,7 |

7,2 |

8,5 |

10 |

10,8 |

12 |

|||

|

Number of tines with working bodies, pcs. |

16 |

24 |

32 |

36 |

42 |

48 |

52 |

|||

|

Number of spring teeth of harrows, pcs. |

16 |

24 |

30 |

36 |

42 |

48 |

50 |

|||

|

Number of rows of spring teeth, pcs. |

3 |

|||||||||

|

Number of rows of hoes, pcs. |

5 |

|||||||||

|

Operating width of the cultivator tine, mm |

260 |

|||||||||

|

Operating depth, cm: with a flat hoe/with an installed tine point or chisel |

3-12/12-20 |

|||||||||

|

Operating speed, km/h |

10-12 |

|||||||||

|

Transport speed, km/h, not more than |

20 |

|||||||||

|

Dimensions in the working position, mm: |

length |

9200 |

9200 |

9200 |

9200 |

9200 |

9200 |

9200 |

||

|

width |

3700 |

5800 |

7300 |

8600 |

9900 |

10900 |

12100 |

|||

|

height |

2100 |

2100 |

2100 |

2100 |

2100 |

2100 |

2100 |

|||

|

Dimensions in the transport position, mm: |

length |

9200 |

9200 |

9200 |

9200 |

9200 |

9200 |

9200 |

||

|

width |

3700 |

5800 |

6000 |

6000 |

6000 |

6000 |

6000 |

|||

|

height |

2100 |

2100 |

2100 |

2100 |

3900 |

4400 |

4800 |

|||

|

Weight, kg |

3500 |

4100 |

6100 |

7200 |

8300 |

8900 |

9600 |

|||

|

Service life, years |

7 |

|||||||||

|

Number of operating staff, persons |

1 |

|||||||||

|

Tractor rating, h.p. |

130-160 |

180-280 |

280-300 |

300-350 |

350-400 |

400-420 |

420-450 |

|||

.png)